3D-printed chip detects multiple foodborne bacteria

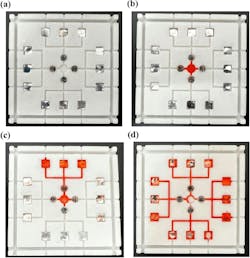

Researchers from Guangdong University of Technology in China, alongside a team from Pudong New District People’s Hospital, designed a microfluidic chip they can 3D-print that uses light to simultaneously detect multiple types of pathogens in food (see Fig. 1 and video).

“Detecting foodborne pathogens is challenging due to their diverse nature and the various environments in which they can thrive,” says Guangdong researcher Dr. Silu Feng, first author of the study published in AIP Advances. “By developing a more comprehensive and faster detection method, we aim to enhance the ability to promptly and effectively manage food safety risks.”

The particulars

The team’s chip technology is an aptamer-based nano-interferometer that identifies four foodborne pathogens: listeria, Escherichia coli (E. coli), salmonella, and staphylococcus aureus (staph A). It includes four detection zones capable of detecting the different pathogens individually (see Fig. 2). Each zone contains three detection chambers equipped with pathogen sensors that are prepared using anodic aluminum oxide—a self-organized material with a honeycomb-like structure formed by high-density arrays of uniform, parallel nanopores. The three detection chambers are connected to a circular inlet at the center of the chip via a trifurcating (split) liquid channel.

Detection results are obtained by comparing the shifts in the reflective spectrum of the sensors, Feng explains, and the sensor spectrum is recorded before detection. The detection process then begins by adding the test liquid to the chip inlet, which flows through four channels connected to the inlet and into the four detection zones.

“We can control the flow of the liquid into the detection chambers by regulating the valves,” Feng says. “When the test liquid enters the detection chambers, aptamers bound to the sensor surfaces specifically capture the pathogens in the liquid.”

At that point, a red shift occurs in the sensor spectrum, with the magnitude of the shift being more pronounced at higher pathogen concentrations in the liquid.

Existing methods for detecting foodborne pathogens include culture-based methods such as polymerase chain reaction (PCR), and enzyme-linked immunosorbent assay (ELISA). These methods, while accurate, are very time-consuming, and lead to delays in identifying and addressing potential outbreaks. Overall, Feng says these approaches are also limited by the need for specialized equipment and trained personnel, as well as challenges detecting multiple pathogens simultaneously.

Clearing hurdles

The innovations of this chip “lie primarily in the application of optical detection for foodborne pathogens, allowing for an intuitive understanding of the detection results,” Feng says.

The technology enables multiplex detection of foodborne pathogens. The researchers can identify various pathogens in a single test, which reduces the time needed for detection. Valves in the microfluidic chip can be controlled, as well, for customizable detection. Basically, Feng explains, if only E. coli needs to be detected, the valve leading to the E. coli detection zone can be opened while closing the other three valves, allowing for the exclusive detection of E. coli.

“The current limitations of foodborne pathogen detection technologies include relatively low detection efficiency,” Feng says. “Our method can quickly and effectively detect multiple different pathogens, and the results are easy to interpret, significantly improving detection efficiency.”

Moving forward

The research team is now working to optimize the microfluidic chip. This could potentially include incorporating new and different 3D materials to enhance sensitivity.

“Using nanostructured materials with a high surface area and specific surface chemistry could enhance signal response and potentially lower detection limits,” Feng says.

Detection performance could also be enhanced by adjusting the design and operational parameters of the nano-interferometer. For example, the wavelength and intensity of the light source, and sensitivity and response time of the detector. Such improvements could make the interferometer more widely applicable and reliable in fields like food analysis.

About the Author

Justine Murphy

Multimedia Director, Digital Infrastructure

Justine Murphy is the multimedia director for Endeavor Business Media's Digital Infrastructure Group. She is a multiple award-winning writer and editor with more 20 years of experience in newspaper publishing as well as public relations, marketing, and communications. For nearly 10 years, she has covered all facets of the optics and photonics industry as an editor, writer, web news anchor, and podcast host for an internationally reaching magazine publishing company. Her work has earned accolades from the New England Press Association as well as the SIIA/Jesse H. Neal Awards. She received a B.A. from the Massachusetts College of Liberal Arts.