BIOMEDICAL IMAGING: 3D digital holograms visualize biomedical applications

Javid Khan

After 15 years of R&D, holographic technology is ready to re-emerge. Digital holograms are now mature enough for commercialization in all sorts of fields including biomedical imaging, scientific visualization, engineering design, art, and advertising. In particular, three-dimensional (3D) digital holograms can be created from almost any type of biomedical datasets from protein database files to medical scans. Next-generation holographic displays are being designed for medical imaging to depict volume data from computed tomography (CT), magnetic resonance imaging (MRI), and ultrasound scans.

A holographic timeline

Scientific literature says that the best way of making 3D images is to recreate the light field of the scene.1 This can be achieved through holography and similar approaches such as integral imaging.

Unfortunately, true holography has not lived up to its expectations, which were largely driven by the realms of science-fiction fantasy following the iconic Star Wars movie in 1977. While static analog holograms were popular for a while during the 1980s and 1990s, it soon became clear that making static holograms needed to move beyond the laboratory and that dynamic holographic displays were "in a land far, far away." Hence, holography went underground in the 1990s with just a few European companies, some Japanese groups, and the U.S. military developing digital hologram printing technology. Holographic display research was performed only by high-end research facilities like MIT Media Lab (Cambridge, MA).

The recent proliferation of 3D content has created a resurgence of interest in this field—a revival due to the explosion of 3D data from many sources including geographical data, medical scans, CAD design, simulations, low-cost depth scanners, cinema/TV, and 3D printing.

Holoprinter technology

Digital holograms are fabricated using holoprinter or holographic printing devices. These are industrial-scale machines that can manufacture full-color, purely digital-reflection holograms in a manner that is repeatable and reliable. Available from a handful of manufacturers such as Geola (Vilnius, Lithuania), View Holographics (St Asaph, Wales) and Zebra Imaging (Austin, TX), holoprinters use a variety of techniques to produce multiplexed stereographic holograms from computer graphics or real-world scenes.

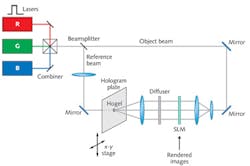

The digital hologram comprises a matrix of holographic pixels, also known as holopixels or hogels. The holopixels are created by the interference of red, green, and blue (RGB) lasers in a holographic medium such as a photopolymer (by Bayer or DuPont) or silver halide film (see Fig. 1). A holoprinter includes RGB lasers, a spatial light modulator (SLM), beam-steering optics, and a computer to show the images on the SLM as well as control the whole system. The laser-writing scheme uses an object and reference beam pair. The object beam is modulated via the SLM with 2D information synthesized from the scene. Optics are held stationary whereas the holographic medium is mounted on an x-y translation stage and moved relative to the lasers, which are usually arranged vertically in-line and operate on different holopixels in parallel. The stage is moved continuously in a raster-scan fashion.

Holopixels are written with RGB pulsed lasers with pulse widths around 40 ns and energies up to 10 mJ. The RGB holopixels are spatially overlaid, with holopixel dimensions now shrinking to submillimeter diameters—currently around 0.8 mm—and trending even smaller to 0.5 mm or even 0.25 mm. At such small dimensions, the holopixels are no longer visible with the human eye, making it possible to create photo-realistic digital holograms.2 A digital hologram fabricated in this manner typically takes several hours for a page-sized print.

For replay (viewing) of the 3D image, digital holograms only require a simple, bright point light source for illumination. The holograms produced in this manner are high-quality, full-color reflection holograms, and it is even possible to produce digital holograms that can lie flat, allowing the viewer to walk 360° around the image. A small page-sized digital hologram costs a few hundred dollars to produce, with larger images up to a square meter scaling in price accordingly. The price can be reduced further via holographic replication technology that works like a "holographic photocopier," with RGB lasers to make analog copies of digital holograms in seconds.

Although current holoprinters are somewhat bulky devices with large and powerful lasers as well as mechanics, portable devices are not far off. Pioneer (Kawasaki, Japan) has announced a desktop unit using RGB laser diodes that can produce small card-sized holograms. There is every reason to expect desktop-sized holoprinters no larger than a standard laser printer within the next few years.

Digital holograms

Any type of 3D dataset can be converted to a digital hologram. This could be a physical scan of an object, a mathematical description, molecular data, map/contour data, point cloud, volume data, CAD model data, or even a series of stills or video.

First, the view of a 3D scene has to be computed for each holopixel as seen through its submillimeter aperture by following a precise set of rules depending on the holoprinter. For example, a 200 × 300 mm page-sized hologram with 0.8 mm holopixels requires the generation of more than 90,000 2D images. This is achieved using a combination of commercial computer modeling software with graphics rendering as well as proprietary algorithms or custom hardware engines to perform a series of mathematical transformations to generate the image data for presentation to the SLM.2

Since it is possible to control the light rays emitted from each holopixel, it is feasible to include some limited animation within the digital hologram such as stripping away layers as the viewer moves around the hologram, thus revealing hidden aspects of the image. As most of our images are synthetic, it is also possible to include opacity and fading to highlight features that would otherwise be obscured.

From molecules to anatomical models

Primarily targeted at public dissemination, outreach, training, and education, Holoxica's digital holograms span the entire spectrum of biomedical science from the atomic scale up to a full anatomical figure (see Fig. 2).A protein data base (PBD) file containing all the necessary atomic (structure usually derived from x-ray crystallography) and positional information to describe the structure of atoms, molecules, and proteins can be used to reconstruct a geometrically accurate and to-scale 3D model. Working in collaboration with Manchester University, our first digital hologram in this area was a green fluorescent protein (GFP). We recently fabricated a digital hologram of the well-known DNA double helix structure to celebrate the 50th anniversary of its discovery.

On a larger scale, Holoxica worked with the Clinical Research Imaging Centre (CRIC) at Edinburgh University on a full-color digital hologram of a pair of lungs from a CT scan. The intricate detail of the structure is visualized, including the bronchial tree and lung sacks (pleura) surrounding the airways (alveoli). We have also imaged the liver (from ultrasound scans) and brain. Our most complex hologram to date is a full-length human anatomy hologram created from a synthetic 3D model of a female. This hologram contains three layers of information on the muscle structures, skeleton complete with arteries plus nervous system, and the internal organs. One of the challenges f acing medical education is teaching the 3D structure of the body since most of the material is currently in 2D.

Digital 3D holograms can also aid archaelogy. In 1857, the Rhind Mummy was excavated from a tomb in Thebes by the archaeologist Alexandar Rhind. Despite remaining in its original wrapping at the National Museum of Scotland, the mummy's secrets were finally revealed 155 years later via CT scans. The scans revealed that the Rhind Mummy was an Egyptian female in her late twenties, 1.58 m tall, and dating to around 10 B.C. Holoxica managed to produce an animated hologram of the head and upper torso that reveals different layers of information as the viewer moves from left to right. The first layer is the sarcophagus, or wrapping, peeling away to reveal the face followed by the skull (see Fig. 3). This color-animated, life-sized hologram is currently on display at the MIT Museum in Boston.The future: dynamic, real-time displays

Although the holographic displays research community has been making significant advances in recent years, the prospect of a true holographic display still remains elusive. Holographic displays are still at the basic research stage and require significant technological advances before they become commercially feasible.1 Instead of trying to make the "mythical Star Wars" display, we've taken a more pragmatic approach by asking, what is the simplest holographic display you can make? The answer: a single pixel, or voxel, in 3D space, that can be switched on or off. One voxel is not particularly interesting, so we move on to two voxels and work up from there to 4, 9, 16 voxels, and so on.

Our first-generation proof-of-concept holographic display demonstrator in 2010 was based on a proprietary holographic screen containing spatially multiplexed interference patterns that are easily switched by structured illumination of the light source.3 The second-generation display made earlier this year is based on a holographic optical element (HOE), enabling free-space imaging with arbitrary 3D images floating in mid-air that can change in real time (see Fig. 4).4Interactivity is added with a Kinect motion sensor that allows people to "touch" icons in space and draw objects in mid-air. Immediate applications include head-up displays and novel user interfaces with an added dimension. The images are bright and visible under indoor lighting conditions, and the approach is scalable, leveraging existing manufacturing techniques and using high-end components with some modifications.

References

1. V. M. Bove, "Display Holography's Digital Second Act," Proc. IEEE, 100, 4, 918–928 (2012).

2. H. I. Bjelkhagen and D. Brotherton-Ratcliffe, Ultra-Realistic Imaging: Advanced Techniques in Analogue and Digital Colour Holography, Taylor & Francis Group, London, England (2013).

3. J. Khan et al., "A low-resolution 3D holographic volumetric display," Proc. SPIE, 7723, 77231B-7 (2010).

4. J. Khan et al., "A real-space interactive holographic display based on a large-aperture HOE," Proc. SPIE, 8644, 86440M (2013).

Javid Khan is founder and managing director of Holoxica in the Scottish Microelectronics Centre, The King's Buildings, West Mains Rd., Edinburgh EH9 3JF, Scotland; e-mail: [email protected]; www.holoxica.com.