Microscopy technique could lead to low-cal chocolate

Seeking to find a method of reducing fat content in chocolate, researchers from the Chemical Engineering department at Loughborough University and the Division of Food Sciences at Nottingham University (both in England) used temperature-controlled microscopy to visualize and measure the in-situ growth of fat crystals on the surface of chocolate. The structure of standard chocolate is a crystalline structure of sugar and cocoa solids within a fat matrix.

In basic dark chocolate, for example, the fat constituent can be up to 40%, so chocolatiers are driven to reduce the percentage and thereby create a lower-calorie—but still tasty—version. One possible solution for accomplishing this is to add limonene, an essential oil commonly used as a citrus food flavoring that does not crystallize with the bulk of the cocoa butter chains, but instead reduces the melting temperature of the chocolate by decreasing the chemical potential of the crystal network, the researchers told BioOptics World.

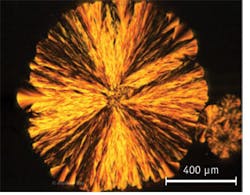

To photograph two sets of chocolate samples, one of which was mixed with limonene, the researchers used a microscopy camera from PixeLINK (Ottawa, ON, Canada) and Linksys32-DV temperature control and image capture software from Linkam Scientific Instruments (Chilworth, England). Both sets were then stored at 20°C and observed over a period of four weeks for microstructure changes and differences between the two mixes. After one day, ~800–1000 μm, feather-shaped spherulites could be observed in the samples containing limonene.