LIGHT SOURCES/CANCER DETECTION/ DENTISTRY: High performance mid-IR sources enable applications such as skin cancer detection

A combination of germanium and tin (GeSn) can create LEDs that emit in the IR wavelength range, around 2 μm. That's the finding of research led by James Kolodzey at the University of Delaware (UD, Newark) and involving colleagues there and at the University at Albany State University of New York (SUNY). The work may have health-care applications, said Kolodzey, particularly in the detection of skin cancer.1

"Germanium-tin alloys may provide a new diagnostic tool for illuminating skin tissue and detecting skin changes visible only in the infrared spectrum. It may also have dental applications," he explained.

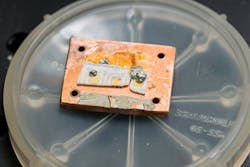

Traditionally, it has been questionable whether GeSn was capable of efficient light emission, but the researchers showed clear and efficient performance in the mid-IR. They doped with boron a GeSn/Ge p-n heterostructure's GeSn layers, which took the crystal structure of the Ge substrate beneath. They observed electroluminescence in the structure with an emission peak at about 0.57 eV (2.17 μm) and a total integrated optical output of 54 μW at a peak current of 100 mA at a temperature of 100 K.

He hopes eventually to develop a GeSn mid-IR laser able to output at higher power and with a beam more easily controlled than an LED. He thinks that this type of tool could aid in drug development or enable laser-surgery techniques.

1. J. P. Gupta, N. Bhargava, S. Kim, T. Adam, and J. Kolodzey, Appl. Phys. Lett., 102, 25, 251117 (2013).