The light that we see ranges from purples to reds, or wavelengths of 400–700 nm. The longer wavelengths of light beyond that are the infrared (IR). The near-infrared (NIR) makes up the first part of the infrared—say, 700 to 2,500 nm.

In NIR spectroscopy, a researcher shines NIR light on a sample and measures the reflected signal or the radiation transmitted through the sample. As noted by Hui Li, NIR product manager at Bruker Optics (Billerica, MA), NIR spectroscopy is fast, does not destroy a sample and can monitor multiple parameters. Other technologies, like high-pressure liquid chromatography (HPLC), might provide more detail in some cases, but researchers might spend a day or more just to prepare samples for such analytical techniques.

Chemical information from light

NIR spectra can be collected one spectrum at a time, a technique called NIR spectroscopy, or by using a focal plane array detector in what is called NIR chemical imaging (NIRCI). The pharmaceutical industry, for example, increasingly relies on NIR instruments. "NIR spectroscopy can be used to monitor the full drug-production process," says Li. In the pharmaceutical industry, executives always look for faster processes, and NIR spectroscopy can provide results in several seconds with some systems and applications. "Since the measurements are so fast," says Li, "you analyze more samples." For example, if a pharmaceutical manufacturer uses HPLC to measure the uniformity of a batch of pills, it requires about 10 pills, which get destroyed, and the results don't come back for a day or two. With Bruker's TANDEM FT-NIR based online tablet analyzer, a manufacturer can do real-time monitoring of pills as they pass on a production line. Bruker's fiber-optic based MATRIX-F FT-NIR instrument can even be fitted with an external multiplexer to monitor up to 48 points of interest, and multiple parameters, such as the analyte concentration in a liquid, can be monitored simultaneously at each measurement point.

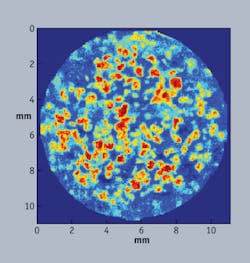

NIRCI is also used in pharmaceutical manufacturing, but mostly in formulation development and troubleshooting. Janie Dubois, product manager of analytical imaging at Malvern Instruments (Columbia, MD) says, "NIR chemical imaging is a perfect fit with the pharmaceutical industry because the spatial resolution and chemical specificity of the technique are in line with the requirements for the analysis of solid dosage forms." The high cost of instrumentation has limited the deployment of NIRCI when manufacturing low-cost products, but being able to see the structure, or composition, of a pharmaceutical tablet, granule or capsule can provide a fast return on investment. This information enables the design of a more stable process or the ability to understand and correct product performance failures.

To give an example of performance, Malvern's SyNIRgi can measure 81,920 spectra in just a few minutes. "It gives something that's like a picture with details of where things are," says Dubois, "and the patterns of agglomeration, preferential positioning or layer thicknesses are all linked to product performance. It finally provides a wealth of information directly correlating with product quality, but accessible in the intact product."

This technology behind SyNIRgi emerged from the declassification of military cameras. The camera technology was developed for applications such as Tomahawk missiles. When it became unrestricted, E. Neil Lewis and his team at the U.S. National Institutes of Health coupled it to a spectrometer; this marked the beginning of IR imaging for biological and industrial applications. Lewis went on to form a company called Spectral Dimensions, which was acquired by Malvern in 2006.

Expanding applications

NIR spectroscopy is widespread in agricultural, food and chemical manufacturing. Dubois mentions that Malvern's instruments are used by researchers at Kansas State University (Manhattan, KS) to monitor wheat milling. "They use it to determine if the milling is making a good mix," Dubois explains. "They can use the results to set up the milling parameters to get the best-quality flour."

In addition, some NIR devices go beyond industrial and laboratory settings. For most types of instrumentation, though, taking a device to the field creates added challenges. In the 1990s, ASD (Boulder, CO) got started in NIR spectroscopy by building instruments for satellite remote-sensing studies. "So our focus has been outside-the-lab measurements," says Brian Curtiss, ASD's co-founder and chief technology officer. For instance, researchers are using ASD NIR instruments to study organisms in the ocean and in coastal waters.

Building a NIR spectrometer that works outside a lab tests a company's design capabilities. "It's a lot easier to put in a bigger light source than to make the spectrometer more optically efficient," says Curtiss. "In the lab, you aren't so worried about weight or power requirements." Those issues, though, become crucial for outdoor use.

Some researchers are using ASD systems to measure the light usage of plants. That requires measuring how much sunlight reaches the plant, and how much light the plant absorbs. So the researchers must measure the ambient illumination. "This light is many times dimmer than you'd use in the lab," says Curtiss, "so you need a more efficient system."To get that added efficiency, ASD relies on gratings and fiber optics with high efficiencies, as well as a detector with high sensitivity. "We develop a design that maximizes the near-infrared photons that pass through the system and reach the detector. That takes lots of modeling, prototyping and testing," says Curtiss.

Also, improved components enhance today's NIR spectrometers. "In the early '90s," says Curtiss, "near-infrared detectors were limited by performance that is a fraction of what they provide today." He adds that water in optical fibers affects the NIR transmission. "The water content is down now, so transmission at the longest near-infrared wavelengths is more than a factor or two better than it was 15 years ago," he explains.

NIR spectrometers could also be used in developing technologies, such as biofuels. "Unlike pharma, where they can tightly control ingredients through recipes and using raw ingredients that are controlled in identification, particle size, etc.," explains Curtiss, "cellulosic biofuels depend on natural feedstocks with lots of variability. You need a way to rapidly characterize those." For example, the selection of enzymes to break down the feedstocks depends on the composition of materials. "Near-infrared spectroscopy is ideal for that," says Curtiss. "You can perform many of these measurements without lots of sample preparation. For example, you could have wood chips on a conveyor and make measurements from a foot or two away."

So from today's drugs to tomorrow's fuels, this light beyond the red makes it easier than ever for scientists to see more.

About the Author

Mike May

Contributing Editor, BioOptics World

Mike May writes about instrumentation design and application for BioOptics World. He earned his Ph.D. in neurobiology and behavior from Cornell University and is a member of Sigma Xi: The Scientific Research Society. He has written two books and scores of articles in the field of biomedicine.