IMEC tunes plasmon resonances; potential uses in biomolecular detection

Leuven, Belgium--Researchers at IMEC have developed a way to tune plasmon resonances; they do this by breaking the symmetric geometry of the nanostructures. Such broken symmetry can lead to strongly enhanced local electric fields. A potential application is the detection of biomolecules via surface-enhanced Raman scattering (SERS).

Metal-based nanophotonics (plasmonics) is a field concerned with manipulating and focusing light on nanoscale structures that are much smaller than conventional optical components. Plasmonic technology has the potential to be used in future applications such as nanoscale optical interconnects for high performance computer chips, highly efficient thin-film solar cells, and extremely sensitive (bio)molecular sensors.

Silver and gold

Plasmonic devices can be made from nanostructured metals, with gold and silver being especially useful. When such nanostructures are illuminated with visible to near-IR light, the excitation of collective oscillations of conduction electrons (surface plasmons, in other words) generates strong optical resonances, focusing electromagnetic energy at deep-subwavelength scales.

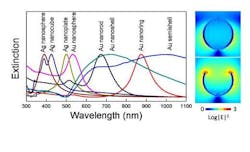

The resonance spectra of the metallic nanostructures strongly depend on their geometry. IMEC has extensive experience in synthesizing various shapes of nanostructures to tune the resonances from the ultraviolet to the near-IR region. Examples of such shapes are nanospheres, nanocubes, nanorods, nanoshells, and nanorings.

Many shapes

The IMEC researchers precisely tune the plasmon resonances by breaking the symmetric geometry of the nanostructures, using a combination of bottom-up and top-down fabrication processes. This allows making a geometrical transition from nanocubes to nanoplates,1 from nanoshells to semishells and nanobowls,2, 3, 4 or from nanocages to open nanocages.5

Differing shapes of plasmonic nanostructures have differing extinction spectra (figure, left). The electric-field distribution around these structures can be calculated for example for a gold nanoshell and a semishell (figure, right).

Combining bottom-up and top-down fabrication turns out to be a cost-effective method to obtain large areas covered with engineered metal nanostructures. The dimensions are still set by the bottom-up fabrication procedures, and the geometrical tweaking occurs through well-characterized top-down fabrication techniques such as metal evaporation and ion milling.

IMEC has gained insight into the optical properties of these nanostructures using a combination of electromagnetic simulations and advanced optical spectroscopy, paving the way to tailoring the optical properties of metal nanostructures for specific applications.

REFERENCES:

1. Jian Ye et al., Nanotechnology, 2008, 19, 325702)

2. Jian Ye et al., Journal of Physical Chemistry C, 2009, 113, 3110

3. Jian Ye et al., Langmuir, 2009, 25, 1822

4. Jian Ye et al., ACS Nano, 2010, 4, 1457)

5. Jian Ye et al., Optics Express, 2009, 17, 23765

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.