Optoacoustic sensor is minimally invasive for examining coronary blood vessels

Recognizing that piezoelectric components have not yet been sufficiently miniaturized to be inserted into blood vessels for ultrasonic coronary blood vessel examination, an international team of researchers at Laser Zentrum Hannover e.V. (LZH; Germany) and the Technion – Israel Institute of Technology (Haifa, Israel) are working on an optoacoustic sensor for medical ultrasonic technology. The minimally invasive sensor inserts directly into coronary blood vessels, enabling a more detailed image of the vessel than is possible using external methods.

Related: The wide-ranging benefit of photoacoustic commercialization

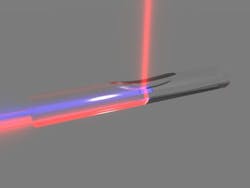

The research team's technology is based on optical interferometry, where the intravascular module is equipped with an optoacoustic imaging sensor that can provide an internal image of blood vessel tissue at a depth up to 1 mm. To achieve this, a guided laser pulse from an illuminating fiber is first absorbed by the tissue, and the resulting ultrasonics are then guided to a fiber-based ultrasonic detector via an acoustic lens. By transforming this signal into an optical signal, a complete image of the vascular walls can be made. An optical interferometer recognizes deviations in the reflection pattern, making the detection of abnormal or disease-based changes in the tissue possible.

Diagnosis of diseases and disorders like arteriosclerosis will be much simpler since the sensor should have a significantly higher sensitivity and resolution when compared to current methods.

The scientists in the Laser Micromachining Group at LZH are developing the process engineering necessary for the production of the acoustic lenses that will be inserted directly into the glass substrate. To do so, specific areas of the substrate will be removed first using the laser and then polished. Further parts of the intravascular sensor module are, apart from the lens, an ultrasonic detector element and a lighting fiber for ultrasonic stimulus. The design and the conversion of the signals into an image that can be used for diagnostics is being developed by the scientists at Technion.

For more information, please visit www.lzh.de.

BioOptics World Editors

We edited the content of this article, which was contributed by outside sources, to fit our style and substance requirements. (Editor’s Note: BioOptics World has folded as a brand and is now part of Laser Focus World, effective in 2022.)