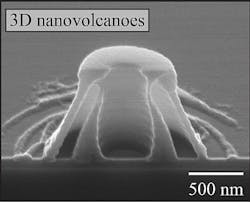

Researchers at North Carolina State University (Raleigh, NC) have created ânano-volcanoesâ by shining various colors of light through a nanoscale âcrystal ballâ made of a synthetic polymer. These nano-volcanoes can store precise amounts of other materials and hold promise for new drug-delivery technologies.

Related: âCornell dotsâ get single pore makeover for more targeted drug delivery

The researchers create the nano-volcanoes by placing spherical, transparent polymer nanoparticles directly onto the flat surface of a thin film. They then shine ultraviolet light through the transparent sphere, which scatters the light and creates a pattern on the thin film. The thin film is made of a photoreactive material that undergoes a chemical change wherever it has been struck by the light. The researchers then submerge the thin film in a liquid solution that washes away the parts of the film that were exposed to light. The material that remains is shaped like a nanoscale volcano.

âWe can control the pattern of light by changing the diameter of the nanoparticle spheres, or by changing the wavelengthâor colorâof the light that we shine through the spheres,â says Xu Zhang, a doctoral student in mechanical and aerospace engineering at NC State and lead author of the paper describing the work. âThat means we can control the shape and geometry of these structures, such as how big the cavity of the nano-volcano will be.â

The researchers developed a highly accurate computer model that predicts the shape and dimensions of the nano-volcanoes based on the diameter of the nanoscale sphere and the wavelength of light.

Because these structures have precisely measured hollow cores and openings at the âmouthâ of the nano-volcanoes, they are good candidates for drug-delivery mechanisms. The size of the core would allow users to control the amount of the drug a nano-volcano would store, while the size of the opening at the top of the nano-volcano could be used to regulate the drugâs release.

âThe materials used in this process are relatively inexpensive, and the process can be easily scaled up,â says Dr. Chih-Hao Chang, an assistant professor of mechanical and aerospace engineering at NC State and co-author of the paper. âIn addition, we can produce the nano-volcanoes in a uniformly patterned array, which may also be useful for controlling drug delivery.â

Changâs team is now working to improve its understanding of the release rate from the nano-volcanoes, such as how quickly nanoparticles of different sizes will âescapeâ from nano-volcanoes with different-sized mouths. âThatâs essential information for drug-delivery applications,â Chang says.

âItâs exciting to take our understanding of how light scatters by particles and apply it to nanolithography in order to come up with something that could actually help people.â

The paper was published on June 12, 2013, in the journal ACS Nano; for more information, please visit http://pubs.acs.org/doi/abs/10.1021/nn402637a.

-----

Follow us on Twitter, 'like' us on Facebook, and join our group on LinkedIn

Subscribe now to BioOptics World magazine; it's free!