Doubts have been raised about the widespread assumption that 1550 nm would be an inherently safer wavelength for automotive lidars than the 905 nm wavelength used in the current generation of systems. As often happens with laser safety, the matter is not as simple as it might seem, and in some cases 1550 nm light may be able to cause eye injuries or be detected by—or damage—silicon sensors that nominally cut off at shorter wavelengths.

The 905 nm wavelength was chosen for early automotive lidars because pulsed diode laser emitters were readily available, relatively inexpensive, and could fit easily in spinning lidars mounted atop autonomous cars. However, the eye does transmit 905 nm light to the retina, so eye-safety rules require limiting emission at that wavelength, which effectively limits the range of many car lidars to around 100 m. That range is adequate to spot hazards and stop self-driving robo-taxis moving at 20 to 30 mph in urban centers, but it is not considered adequate for self-driving cars at highway speeds. That limit and the high cost of lidars are major reasons that Tesla Motors does not use lidar in its Autopilot system.

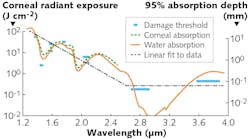

The cornea, lens, and aqueous and vitreous humors in the eye absorb wavelengths longer than 1400 nm so strongly that essentially no light reaches the retina, and the threshold for retinal damage is much higher at longer wavelengths than in the visible and near-infrared, says laser safety consultant Ken Barat. Thus, lidars in the 1550-nm communications band can safely emit higher power and range longer distances than at 905 nm. That’s a clear attraction for automotive applications, but it does not make 1550 nm eye-safe at any power. Laser pulses of sufficient power at 1550 nm can damage the cornea and lens, but the thresholds are higher than for the retina at shorter wavelengths because the cornea and lens are less sensitive than the retina and the light is not focused within the eye as it is on the retina.

Velodyne Laser (San Jose, CA), a pioneer in car lidar, says its 905 nm lidars are classed as Class 1, incapable of causing eye damage under any conditions, because the two milliwatt beams are scanning continually, so they would sweep across a person's eye in about a millisecond. Velodyne adds that 1550 nm lidars may require higher power for a given range because the longer wavelength suffers more scattering from atmospheric moisture.

Early developers disclosed few details about their 1550 nm lidars, so many observers assumed they also used diode lasers. However, fiber lasers offer better beam quality and have other performance advantages. “As far as we know, everyone using 1550 nm for automotive lidar is using some form of fiber amplification” pumped at wavelengths below one micrometer, says Matthew Weed, director of technology strategy for Luminar Technologies (Orlando, FL). Luminar’s fiber lidars amplify seed pulses from diode lasers.

Luminar’s lidars also meet Class 1 safety standards. Their design suppresses light at wavelengths outside the 1540 to 1560 nm range to improve power efficiency and reduce noise. Testing confirmed the suppression of other wavelengths, but the company found that under certain circumstances silicon sensors, which normally cut off around 1100 nm, can respond to their 1550 nm lidar. "The physics for this has a few different explanations," Weed says, such as heating or two-photon absorption.

Camera chips not safe, either

An incident early this year at the Consumer Electronics Show in Las Vegas suggested that 1550 nm lidars might damage camera chips under certain circumstances. After taking pictures of a car equipped with a 1550 nm lidar from AEye (Pleasanton, CA), Jit Ray Chowdhury, a Silicon Valley engineer, found yellow spots and evidence of chip damage on his digital photos. Unfortunately, he and AEye were unable to establish contact quickly, and Chowdhury discarded the damaged camera in process of moving to a new residence before AEye could examine it. That left the question of what happened to the camera chip inside unresolvable.

The damage claim puzzled AEye because they had seen no problems during earlier photography of operating lidars. The company has attracted attention by claiming a 1000 m range for its lidar, which can record up to one million points per second with pulses lasting less than 10 ns and average power less than 1 W. The big concerns are not consumer cameras, but the cameras that self-driving cars use along with lidars to map the local environment—as well as the eyes of humans along the way.

As long as emission from a 1550 nm lidar is limited to that band, the primary eye-safety issue is burns on the surface of the cornea, which occur at powers significantly higher than those of retinal damage from wavelengths shorter than 1400 nm. There has been a claim that one person suffered a corneal burn from a 1550 nm laser that had been assessed as “eye-safe at the exit aperture,” but details remain private. Based on what little information is available, safety consultant and optical radiation biophysicist Bruce Struck says, “It seems possible but would have required an unusual viewing situation.” Nonetheless, he says that “we need thoughtful and comprehensive measurements.”

A potential long-term danger is failure to filter out short-wavelength infrared pump light, a problem the National Institute of Standards and Technology found was common several years ago in green laser pointers. Fiber-laser lidars are pumped by diode lasers emitting in the 900 nm band, which can pose a retinal risk. Careful design and manufacturing can prevent hazardous leaks, but the NIST study shows that some makers of inexpensive lasers cut corners.

Jeff Hecht | Contributing Editor

Jeff Hecht is a regular contributing editor to Laser Focus World and has been covering the laser industry for 35 years. A prolific book author, Jeff's published works include “Understanding Fiber Optics,” “Understanding Lasers,” “The Laser Guidebook,” and “Beam Weapons: The Next Arms Race.” He also has written books on the histories of lasers and fiber optics, including “City of Light: The Story of Fiber Optics,” and “Beam: The Race to Make the Laser.” Find out more at jeffhecht.com.