Developing new markets with dual-use technology—An interview with Gregory Quarles

Gregory Quarles has a long history of technology and management experience in the photonics community and has an extensive network encompassing industry, academia, and government. In early 2019, he took on a new challenge as CEO of Applied Energetics in Tucson, AZ. He did so after holding the position of Chief Scientific Officer for The Optical Society (OSA), and previous executive positions at B.E. Meyers & Co. and II-VI Incorporated. He holds a BS, MS, and PhD in physics from Oklahoma State University.

Conard Holton: Applied Energetics is a relatively small company that specializes in directed-energy technology, ultrashort-pulse lasers, and optical technologies for defense, medical, and manufacturing applications. What attracted you to the opportunity?

Gregory Quarles: The primary reasons were a deeply committed and strategically focused board of directors, the potential for establishing market share leadership, and a tremendous intellectual property (IP) portfolio. Applied Energetics has a portfolio with 26 current patents and 11 more held under secrecy orders by the U.S. Government. This IP covers directed-energy (DE) technology, laser-guided energy (LGE), and ultrashort-pulse (USP) laser technology, with multiple dual-use applications (see figure).CH: Applied Energetics was founded as a joint venture with Raytheon—how has it evolved and what is the company culture like?

GQ: The original founders were all previously Raytheon employees, including their Directed Energy Division Chief Scientist, Stephen McCahon. In 2002, they formed Ionatron in Tucson, which became publicly traded on NASDAQ in 2004. The basic initial concept was to combine a significant early-stage venture capital infusion with rapid product development for insertion into commercial sectors, with parallel technology development for U.S. DoD test and evaluation. Their primary focus as a corporation was to secure IP in the LGE space and to prove it capable of being deemed a validated DE source.

In 2008, they changed their name to Applied Energetics (AE) and continued to expand their IP portfolio to include USP lasers and Laser Induced Plasma Channel (LIPC) technology. They successfully developed and deployed multiple laser-based technologies into the field for testing and full utilization. Between 2002 and 2018, the focus of the company was almost exclusively on the innovation and development of optical source technology for the defense sector.

Our culture has changed over these past eight months, and now comprises a smart, highly calculating, risk-taking environment that enables rapid innovation and execution in high-payoff, high-risk ventures that can make significant impacts on both DoD and commercial markets. Our innovation focus is to look at global applications of the sources ranging from the UV to far-infrared that we are developing to see if they can be used in areas spanning the optical imaging realm, the materials processing markets, for endoscopy and microscopy, or in the defense and security markets.

CH: Tell us a bit about laser-guided energy technology and its potential applications?

GQ: This technology utilizes USP lasers to generate optical filaments in the atmosphere. After the laser generates the filaments, and the laser pulse has passed, there is a residual modification of the air remaining down the filamentation trail. A separate high voltage-generating device is then discharged, and the filamentation trail directs the electrical discharge pathway for the LGE process. AE owns a majority of the IP in this space and we have developed and deployed several mobile platforms covered by these patents.

Most of the applications for LGE fall within the defense sector. These applications include a broad range of counter sensor and electronic effects, anti-IED interdiction, vehicle stopping from a distance, and non-lethal to lethal effects. LGE is considered by the U.S. DoD to be a third DE weapon technology, in addition to high-power laser and microwave, and its effects are fundamentally different since they are a combination of both very high peak electrical current flow at high voltage and an accompanying very high peak-power RF generation directly on the target.

CH: How and over what timeframe will directed-energy weapons become widely adopted?

GQ: There has been a strong and growing investment in directed-energy platforms globally for the past few decades. In the U.S. alone, the government investment has grown from $543 million annually in 2017 to $1.2 billion in 2019, and could potentially grow to over $1.8 billion by 2021. Currently, there are already multiple DE platforms being mobilized by U.S. DoD stakeholders, with most being continuous-wave solid-state laser systems ranging in output power from tens of kilowatts to over 100 kW. Similar systems are being developed in many other countries around the world.

CH: We usually associate USP lasers with specialized but fast-growing manufacturing and biomedical applications—what is your perspective on opportunities in these markets and in defense applications?

GQ: Our team at AE knows that there are multiple opportunities for USP lasers in the defense sector. There are numerous threats for which USP lasers could be a solution, including a proliferation of electronics and sensors, swarms of drones and unmanned aerial vehicles in the urban warfare space, new hypersonic threats, ever-expanding requirements for facility security, and mitigating communication hazards.

CH: Many companies in photonics make products for both defense and commercial applications. What does it mean to be a dual-use technology company today?

GQ: It is exciting and invigorating to drive towards success as a dual-use company in the current market. AE must focus on the strategic plan and technology roadmap with a keen eye towards driving innovation and structuring IP with technology demonstrations that can be of use to both the manufacturing and defense sectors. Dual-use technologies also provide us the opportunity to leverage separate short-term markets and investment to gain entry into larger markets that would otherwise be too capital-intensive as a new start. This approach presents our management with a possibility to force-multiply investment dollars, gaining traction on numerous ventures with the same dollars spent.

CH: Does it limit your options, provide more avenues for growth, and/or basically impose a completely different management approach?

GQ: Balancing the corporate growth through a two-pronged pathway requires a specialized workforce, strong personal and professional ties to multiple markets, and a thoroughness with testing and evaluation. Focusing on just one market and not enforcing rigor in the innovation space can lead a company to become blindsided, but with a well-integrated and diverse skillset, it is possible to exhibit growth and product insertion across multiple sectors.CH: How did your own background in the industry and as CSO for the OSA help?

GQ: I have been blessed with working in the optics and photonics field for the past 35 years, and most of my time has been spent in the defense and industrial sectors. My time with OSA provided me the opportunity to work with phenomenal volunteers and see cutting-edge research globally, some of which may have the opportunity to be incorporated into the markets that AE is pursuing.

Just as importantly, my previous experiences have allowed me to learn from the best leaders and mentors in the manufacturing and defense sectors. All of these paths have helped to build a world-class Rolodex of friends and colleagues at all levels of government, industry, and academia.

CH: There must be many challenges in attracting the specialized talent needed for your business. What has been your approach and how is it working?

GQ: In this first eight months of being at AE, the talent search has been better than expected. The first phase of acquiring talent was through the acquisition of the assets of Applied Optical Sciences in Tucson. This acquisition occurred within my first 60 days on the job and resulted in bringing Dr. McCahon—one of the original founders of AE—back to the organization as Chief Scientist. Other talent is being brought in from local hires.

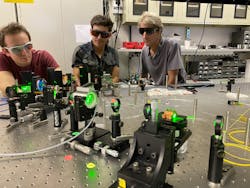

I must say that Tucson and all of Arizona are very talent-rich. It is a top-five U.S. player in both aerospace and defense manufacturing. There are world-class professors and students at the University of Arizona College of Optical Sciences, multiple small businesses in the optics and photonics space in Phoenix and Tucson, and a strong defense sector, including Raytheon, Honeywell, Northrop Grumman, General Dynamics, and Boeing. Our current staff includes several students that are exceptionally talented and contributing to AE’s success.

Conard Holton | Editor at Large

Conard Holton has 25 years of science and technology editing and writing experience. He was formerly a staff member and consultant for government agencies such as the New York State Energy Research and Development Authority and the International Atomic Energy Agency, and engineering companies such as Bechtel. He joined Laser Focus World in 1997 as senior editor, becoming editor in chief of WDM Solutions, which he founded in 1999. In 2003 he joined Vision Systems Design as editor in chief, while continuing as contributing editor at Laser Focus World. Conard became editor in chief of Laser Focus World in August 2011, a role in which he served through August 2018. He then served as Editor at Large for Laser Focus World and Co-Chair of the Lasers & Photonics Marketplace Seminar from August 2018 through January 2022. He received his B.A. from the University of Pennsylvania, with additional studies at the Colorado School of Mines and Medill School of Journalism at Northwestern University.