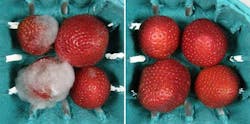

CLEO can be a great place to come upon unexpected applications of photonics. One that caught my eye this year was the use of deep-ultraviolet LEDs to lengthen the storage lifetime of strawberries, an important concern when rhubarb-strawberry pie is a household favorite.

Strawberries are a fragile fruit that must be picked when near ripe, and most supermarket berries come from Florida and California, so they must be packed carefully in plastic "clamshells" and rushed to stores. Inevitably they carry mold spores from the field, so the challenge is to get the fresh berries to the table before they sprout furry mold. Hermetically sealing them inside plastic filled with nitrogen and oxygen can get them across the country safely, but the spores can germinate when exposed to air in stores or home refrigerators.

Flashes of germicidal UV from mercury lamps have been shown to stretch the useful lives of exposed strawberries. However, mercury lamps are bulky, fragile, hazardous, require skilled operators, and are inefficient at low temperatures, so they can't be used in refrigerated trucks. Steven Britz of the Department of Agriculture's Food Components and Health Laboratory (Beltsville, MD) decided to try more compact deep-UV LEDs instead.Britz had been studying UV-LEDs for use in greenhouses, where windows block the solar UV needed to stimulate the growth of antioxidants important for human health. The UV LEDs emit much less power than mercury lamps, but they operate better at cold temperatures, so they can illuminate berries for a longer time in a cooler as they were transported or stored. They also emit at a narrow range of wavelengths, to aid fruit preservation. Working with deep UV-LED maker Sensor Electronic Technology (Columbia, SC) and an unnamed refrigerator company, he set up a test cooler and illumination system and loaded them with supermarket berries and moist air.

After nine days, the berries still looked fresh, more than twice the time usually needed for mold to grow, he reported on June 9, 2013, at CLEO in San Jose. The illuminated berries lost only 5% of their original weight, avoiding the drying in standard home refrigerators. And the anthocyanin compounds that give berries their bright color and nutrient value remained at high levels.

The next step is interesting someone in developing a UV-illuminated refrigeration system. Britz thinks the most likely approach would be UV-resistant cases in store or home refrigerators. A switch would turn the UV LEDs on when the door closed, and off when a person opened the case, preventing human exposure. The UV emission might extend the life of other fruits as well. Maybe it would even help keep the rhubarb.

Jeff Hecht | Contributing Editor

Jeff Hecht is a regular contributing editor to Laser Focus World and has been covering the laser industry for 35 years. A prolific book author, Jeff's published works include “Understanding Fiber Optics,” “Understanding Lasers,” “The Laser Guidebook,” and “Beam Weapons: The Next Arms Race.” He also has written books on the histories of lasers and fiber optics, including “City of Light: The Story of Fiber Optics,” and “Beam: The Race to Make the Laser.” Find out more at jeffhecht.com.