I did not cover silicon Raman lasers in my July Photonic Frontiers article on silicon photonics because my focus was on near-term applications in data centers. But a micrometer-scale silicon Raman laser described in the June 27, 2013 Nature could lead to some interesting possibilities on a longer time scale.

When it was first demonstrated in 2004, Raman laser action in silicon was heralded as a breakthrough in silicon photonics. However, like all Raman lasers, it required optical pumping with an external laser source to excite a Stokes-shifted emission at a somewhat longer-wavelength transition in silicon. Chip developers seeking a new approach to optical interconnections had been hoping for an electrically pumped semiconductor laser that could be directly modulated by the drive current. Moreover, early silicon lasers were centimeter-scale, much too large for practical on-chip use, and the lowest previously reported threshold pump power was 20 mW. Developers turned in other directions.

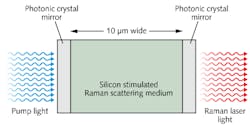

Now, Yashushi Takahashi of Osaka Prefecture University (Sakai, Osaka, Japan) and colleagues have demonstrated a Raman laser only 10 µm long and well matched to the size of a silicon chip. Their key innovation is fabricating a high-Qphotonic-crystal laser cavity that simultaneously resonates at both the 210.0 THz frequency (1428 nm wavelength) of the pump laser, and the 194.4 THz (1543 nm) of the Stokes-shifted Raman emission from vibrating silicon atoms.Their design incorporates a heterostructure nanocavity formed from a line-defect waveguide that confines the pump light and the Raman-scattered light in two separate modes, with their frequency spacing precisely matching the 15.6 THz Raman shift in silicon. The product of the Q factors of the two modes can exceed 1011, and their volume can be reduced to a cubic wavelength. Because the strength of the light-atom interaction depends on the quality factor divided by cavity volume, Takahashi writes, this causes "drastic enhancement of the Raman gain." That allows continuous-wave laser operation at a threshold of only 1 μW, and pumping at 2.5 µW produced more than 0.1 µW of output.

The researchers hope to eventually reduce pump threshold below 0.1 µW. That's so low that spontaneous emission from silicon devices integrated on the chip might suffice, avoiding the need for off-chip optical power supplies needed by current silicon photonics. That would be an impressive achievement.

About the Author

Jeff Hecht

Contributing Editor

Jeff Hecht is a regular contributing editor to Laser Focus World and has been covering the laser industry for 35 years. A prolific book author, Jeff's published works include “Understanding Fiber Optics,” “Understanding Lasers,” “The Laser Guidebook,” and “Beam Weapons: The Next Arms Race.” He also has written books on the histories of lasers and fiber optics, including “City of Light: The Story of Fiber Optics,” and “Beam: The Race to Make the Laser.” Find out more at jeffhecht.com.