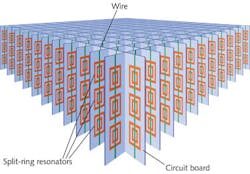

Metamaterials are synthetic materials that offer ways around the limitations of conventional optical materials, such as negative refractive indices and optical cloaking. But metamaterials have their own limitations that arise from the inherent limitations of the materials used to make them, such as the low melting temperature of gold films. In an invited talk December 2, 2013, at the Fall Materials Research Society meeting in Boston, Vladimir Shalaev of Purdue University (West Lafayette, IN) quoted the father of metamaterials, Sir John Pendry, as saying that new materials would inspire new metamaterials.

Dielectrics and metals have been the building blocks of the first generation of metamaterials, with metals such as gold and silver serving as plasmonic conductors. Finding better plasmonic materials is the first priority. "Stability is a problem," Shalaev said. "Gold will melt, move, or fuse" at relatively low temperatures, and that's a particular problem because heating is part of many plasmonic applications.

Shalaev's group is studying titanium nitride (TiN), a tough material used in drill bits that melts at a temperature three times higher than gold. TiN is a non-stoichiometric compound that, like zirconium, tantalum, and hafnium nitrides, has metal-like properties at visible and infrared wavelengths. TiN is biocompatible and absorbs light at the near-infrared band near 800 nm where biological tissue is relatively transparent, making it promising for local heating in biological applications. He called TiN "plasmonic gold" because it looks like gold and has similar optical properties.Another class of materials attractive for metamaterial and plasmonic applications are transparent conducting oxides such as the indium-tin-oxide (ITO) used in current electronic devices. Shalaev's group is studying aluminum-doped zinc oxide, which when heavily doped acts metallic in the infrared and has lower loss than ITO.

A key practical goal for metamaterial developers is finding materials compatible with the CMOS fabrication technology used for integrated electronic circuits. Developing epitaxial silver has been a huge technology, Shalaev said, so he looks forward to replacing it with plasmonic ceramics like TiN in a new generation of metamaterials. TiN is not ready yet, he says, and development will take time—but he is confident it will be better.

If you want to dig further into the prospects, Shalaev has coauthored a comprehensive review of alternative plasmonic materials, available on his group's web site. Metamaterials have tremendous long-term prospects, but much work remains to realize them. This is an important step on the way.

About the Author

Jeff Hecht

Contributing Editor

Jeff Hecht is a regular contributing editor to Laser Focus World and has been covering the laser industry for 35 years. A prolific book author, Jeff's published works include “Understanding Fiber Optics,” “Understanding Lasers,” “The Laser Guidebook,” and “Beam Weapons: The Next Arms Race.” He also has written books on the histories of lasers and fiber optics, including “City of Light: The Story of Fiber Optics,” and “Beam: The Race to Make the Laser.” Find out more at jeffhecht.com.