Thin-film Coatings: Nanoparticles enhance performance of optical coatings

THERESA HENDRICK

Evolution of the electronics, display, automotive, medical, and solar industries is a key factor driving advances in optical coating materials. While some industries need coatings for substrates that offer exceptional optical clarity, others require optical coatings that are wavelength-specific and excellent conductors of electricity. Since the demands placed on the optical coatings industry are high and varied, optical coating manufacturers are turning to advanced materials experts for assistance.

Quantitative and qualitative enhancements are possible by incorporating advanced and nanoscale materials into optical coatings. The coatings can be deposited onto a substrate from a dispersion to form a film or can be incorporated into hybrid coating materials. Those who are skilled in the art of nanoparticle engineering can create highly customized and optimized materials for specific (and often proprietary) optical systems by considering particle size, shape, cost, scalability, stability, and compatibility during formulation, thereby allowing companies to introduce novel products to the market.

Based on our extensive market research along with customer interviews, certain stand-out materials have the potential to disrupt the optical coating industry, including silver, titania, and zirconia. Moving forward, it will be critical to further optimize and customize these materials to bring about enhanced performance, as well as to explore other multifunctional nanomaterials that can contribute to further advances in optical coatings.

High-refractive-index coatings

In optical coatings, control of refractive index (RI) is essential to achieve desired performance.1 Specifically, we have seen demand for high-RI nanoparticles for incorporation into polymer-based optical coatings. By incorporating a high-RI coating on the light-emitting surface of a device, light can travel more productively in or out of the device, leading to improved efficiency and image quality.2

High-RI polymers are being developed for advanced optoelectronic applications in display devices, light-emitting diodes (LEDs), and organic LEDs (OLEDs). Typical optical polymers have RIs of 1.30 to 1.70, limiting the range of optical applications.3

A promising approach to achieving high-RI (>1.70) coatings is through the incorporation of metal-oxide nanoparticles with organic polymers to create an organic-inorganic hybrid material. The design of nanoparticles is an important consideration in their successful incorporation—specifically, particle size and compatibility with the polymer matrix to avoid aggregation.

Two of the most popular nanoparticles for producing high-RI coatings are titania (titanium dioxide or TiO2) and zirconia (zirconium dioxide or ZrO2). Zirconia has shown success in increasing the RI of a coating when it is surface-modified for compatibility with a polymeric system. When incorporated in preliminary polymeric-based formulations, Cerion functionalized zirconia nanoparticles showed higher RI with increasing ZrO2 content, increasing the RI from 1.5 to 1.71 (for 66 wt% ZrO2) and 1.77 (for 75 wt% ZrO2).

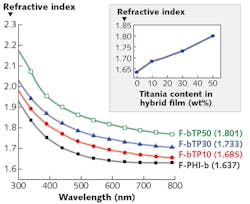

Using high-RI titania, polyimide-nanocrystalline-TiO2 coatings with high weight percent (wt%) TiO2 can form films with high optical transparency. Increasing TiO2 content enables an RI of more than 1.8 with 50 wt% TiO2 (see Fig. 1).4

High- and low-RI nanoparticles can be used to form adjustable RI coatings. For example, titania and silica (silicon dioxide or SiO2) can be used to form coatings on substrates with tunable RI, based on the content of SiO2. Coatings such as these can have other desirable characteristics as well, such as low reflectance and high transmittance.

Antireflective coatings

The surfaces of LEDs and solar cells require antireflective (AR) coatings to provide high transmittance while minimizing reflections of unwanted light.5 These AR properties result from the destructive interference of light as it travels through thin films of differing RI and thickness.

While obtaining near-perfect AR coatings in a research environment is possible, industrial-scale production has been a challenge because of poor manufacturing robustness and contamination that impacts optical performance. However, two materials that show promise for AR coatings are silica and titania because of their RI difference. A multilayer thin film of alternating titania and silica can improve transmittance for bare glass from 92% to 95% for one coated surface and more than 97% for glass coated on both sides. This coating also features multifunctional performance as it absorbs ultraviolet (UV) light, is hydrophobic and oleophobic, and has excellent scratch resistance and adhesion.6

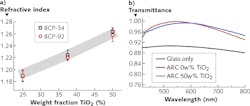

Because of its photocatalytic properties, TiO2 is often used for AR coatings with self-cleaning functionality, as titania can degrade organic contaminants. Modified 4 nm anatase TiO2 nanoparticles incorporated into a block copolymer (BCP) can be processed into a thin film to coat glass or plastic. By incorporating 37.5 wt% TiO2, an optimal RI of 1.22 is achieved for an AR coating on glass (see Fig. 2a).7 With 50 wt% TiO2, the AR coating has a maximum transmittance of about 99.3% with excellent photocatalytic and self-cleaning properties that improve the long-term performance of the substrate used (see Fig. 2b).Nanoparticles of silica (nano-silica) have also been used to produce AR coatings. Nano-silica thin films can be produced via sol-gel processing and coated on glass to bring about significantly reduced light reflection. Deposition time and cycles impact film morphology, and therefore AR properties as well. For an uncoated glass substrate with a maximum transmittance of 91.5%, one 60 s deposition cycle produced a maximum transmittance of 96%. With two deposition cycles of 30 s each, 97.5% transmittance was reached due to a more homogeneous, dense SiO2 layer.8

High-reflection coatings

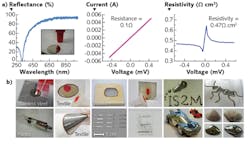

Reflective surfaces find applications in heat dissipation for electronics and in solar-cell cooling. Silver-based coatings offer the highest reflectivity from visible (VIS) through infrared (IR) of all metals and, when present in low amounts as silver (Ag) nanoparticles in a polymer matrix, can form metal mirrors with exceptional light reflectivity and electric conductivity.9 When measured from 250 to 950 nm, Ag polymer coatings have reflectance surpassing 90% (see Fig. 3a). Interestingly, this material has also demonstrated self-healing of surface defects and is easily applied to substrates like textiles, glass, wood, plastic, and steel (see Fig. 3b).There is also interest in creating coatings with high reflectivity in the solar spectrum and high emissivity in the “sky window” region for radiative cooling and thermal management applications. Two-layer coatings that consist of a top reflective layer containing titania nanoparticles, for instance, and a bottom emissive layer such as silica or silicon carbide nanoparticles, have performed well in this application. Rooftop studies confirm that these coatings can cool an aluminum substrate to ambient temperature when exposed to direct sunlight.10

Spectral coatings

Coatings that selectively filter certain wavelengths of light can prevent aging and degradation in certain plastics that are not resistant to UV light, or block near-IR solar energy for solar-driven window cooling.11 In addition to surface-modification methods, an alternative approach focuses on tuning nanomaterials to selectively absorb damaging or unwanted wavelengths and transmitting those that are preferred.

Titania (TiO2) nanoparticle coatings can transmit visible light and strongly absorb UV radiation, whereas zinc oxide (ZnO) provides broad-spectrum protection against UV radiation—especially when in nanoparticle form. Incorporating nanoparticles such as these into coatings can improve protection from UV light while remaining transparent.

Transparent conductive coatings

The market for transparent conductive coatings has exploded because of increased demand for touchscreen displays and thin-film solar cells. Indium tin oxide (ITO) is almost exclusively used in transparent conductive coatings—however, its high cost, high film-deposition temperature, brittleness, and yellow tint means that a reliable replacement is being sought.12

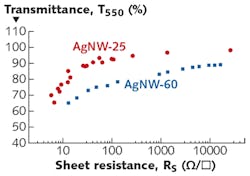

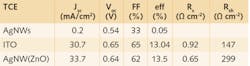

Because replacement materials like carbon nanotubes, graphene, and conductive polymers cannot match the performance of ITO, silver nanowires (AgNWs) have recently emerged as an exciting substitute because of their high transparency and conductivity, low-cost deposition, and resistance to cracking.Silver nanowires can also be combined with other nanomaterials to improve performance for certain applications. A film of AgNWs with a diameter and length of 60 nm and 30–40 µm, respectively, with a thin overlayer of ZnO (AgNW(ZnO)) offers improved connectivity between nanowires and improved adhesion with low-lying surfaces. A solar cell with AgNW(ZnO) transparent conductive electrodes has 13.50% efficiency compared to 13.04% for ITO. It is thought the improved adhesion contributes to the superior performance (see Fig. 5).13

Because of the promise inorganic advanced and nano-sized materials have in optical coatings, many industry leaders are focusing research and development efforts on incorporating these materials into their optical coatings. To overcome hurdles to scalable manufacturing, however, partnerships with inorganic materials experts will be beneficial.

REFERENCES

1. D. Li et al., Sol. Energy Mater. Sol. Cells, 130, 505–512 (2014).

2. H. Ma et al., Nanomater., 6, 3, 1–10 (2016).

3. T. Higashihara and M. Ueda, Macromolecules, 48, 7, 1915–1929 (2015).

4. H. Yen et al., RSC Adv., 3, 17048–17056 (2013).

5. M. Salvaggio et al., Sol. Energy, 125, 227–242 (2016).

6. M. Mazur et al., Appl. Surf. Sci., 380, 165–171 (2016).

7. S. Guldin et al., Nano Lett., 13, 11, 5329–5335 (2013).

8. N. Lari et al., Optik, 126, 24, 5363–5367 (2015).

9. M. Zaier et al., Sci. Rep., 7, 1, 1–10 (2017).

10. H. Bao et al., Sol. Energy Mater. Sol. Cells, 168, 78–84 (2017).

11. T. Otanicar et al., Adv. Opt. Photonics, 8, 3, 541–585 (2016).

12. M. Cann et al., Mater. Today Commun., 7, 42–50 (2016).

13. M. Singh et al., ACS Appl. Mater. Interfaces, 8, 20, 12764–12771 (2016).

Theresa Hendrick is a technical research analyst at Cerion Advanced Materials, Rochester, NY; e-mail: [email protected]; www.cerionadvancedmaterials.com.