IR Detectors: Nanoplate resonator thermal IR detector has ultrashort time constant and high resolution

Thermal detectors, which sense infrared (IR) radiation via its ability to heat material, include devices such as microbolometers, thermoelectric detectors, and pyroelectric detectors. These devices share properties such as low cost and high power efficiency; in addition, they do not require cooling. A newer type of thermal detector based on aluminum nitride (AlN) and called the nanoplate resonant thermal detector (NPRTD) is being developed by Zhenyun Qian and his colleagues at Northeastern University (Boston, MA). The group is showing that these nanoscale devices have fewer limitations than their traditional counterparts.1

In a NPRTD, a piezoelectric AlN nanoplate is excited so that it vibrates at its resonance frequency. Because the resonance frequency is a function of temperature, which (for a properly set up detector) is in turn a function of the received IR radiation, monitoring the frequency provides the desired IR measurement. Because the AlN nanoplate is so small, it has a very short time constant, allowing rapid temporal response.

High thermal resistance and Q factor

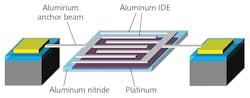

The newest NPRTD device created by Qian and colleagues is built around a 50-nm-thick AlN nanoplate anchored by two Al beams that are only 30 nm thick (see figure), which, also due to their length of a few microns and their careful design, results in a very high thermal resistance of 1.1 x 106 K/W and a high mechanical quality (Q) factor of about 1000—more than a factor of three higher than for earlier NPRTDs (all AlN was removed from the anchor beams to maximize the thermal resistance).

The resonant body itself includes the 50-nm-thick AlN plate, a 30-nm-thick Al interdigitated electrode (IDE) on its top, and a 20-nm-thick platinum plate on its lower surface. Two different experimental devices were fabricated with nanoplate areas of 28 × 30 µm2 and 20 × 22 µm2. The device’s resonance frequency is a function of the “finger” spacing of the interdigitated electrodes; the experimental finger spacing of 4 µm leads to a resonance frequency of about 800 MHz.

The noise-equivalent power (NEP), an often-used performance metric for light sensors, is, for a NPRTD, the frequency fluctuation divided by the detector’s responsivity (a lower NEP is better). The researchers note that, for a given responsivity, the higher the Q, the lower the NEP. Another important metric, the thermal time constant, is a product of the thermal resistance (determined here at least in part by the thermal conductivity of the two anchor beams) and the thermal capacitance (determined here by the volume of the nanoplate).

A high thermal resistance is needed to achieve a low NEP—therefore, the thermal capacitance is an important parameter to minimize, here by making the thickness smaller (although within limits, as the device’s electrical capacitance, which also depends on thickness, cannot be made too small, or the electromechanical coupling of the resonant plate gets worse).

Experimental electromechanical performance of the two devices was measured in a vacuum-probe station, showing Q of 1157 and 902 for the 28 × 30 µm2 and 20 × 22 µm2 devices, respectively. The researchers note that these high figures could be raised even further by improving the AlN thin-film fabrication process. Thermal resistances for the 28 × 30 µm2 and 20 × 22 µm2 devices were 1.12 × 106 K/W and 1.11 × 106 K/W, respectively.

In optical testing, the devices were exposed to 900°C blackbody radiation modulated at 25 Hz by a mechanical chopper (the researchers note that, due to the short thermal time constant of the detector, the device’s frequency shift in response to the radiation was the same for chopping frequencies ranging from 1 to 250 Hz, which was the chopper’s limit). Experimental NEP values were then calculated to be about 485 pW/Hz1/2 and 549 pW/Hz1/2 for the 28 × 30 µm2 and 20 × 22 µm2 devices, respectively. Other tests showed that the absorbed power for the two detectors was on the order of 30% to 40%—a value that the researchers would like to raise, possibly by reducing a hypothesized Fabry-Perot optical resonance in the device.

REFERENCE

1. Z. Qian et al., Appl. Phys. Lett., 115, 261102 (2019); https://doi.org/10.1063/1.5128643.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.