Quantum-dot photodetectors can now detect longwave infrared light

Semiconductor colloidal quantum dots (CQDs) are a promising material for both tunable emission and detection of light. Yesterday, Laser Focus World covered the use of QCDs in LEDs and lasers; today, we report on QCD photodetectors that break through the bandgap barrier that previously limited such detectors to detection in the shortwave IR (SWIR) region—now, this type of device can detect wavelengths of 5 to 10 µm, or the midwave to longwave IR (MWIR to LWIR) regions.

MWIR and LWIR are important for applications that include environmental monitoring, gas sensing, thermal imaging, food and pharmaceutical quality control, and others. The amount of information hidden within this very rich spectral window opens new possibilities for multi- or even hyperspectral imaging. However, existing MWIR and LWIR are typically complex and expensive. There is a strong market need to bring MWIR and LWIR detection and imaging to the consumer market; however, this would most likely require a technology that is low-cost and CMOS compatible and does not impose regulatory concerns.

Lead sulfide (PbS) CQDs have emerged as a cost-competitive and high-performance photodetector technology compatible with CMOS technology, and has demonstrated success in the short-wave infrared (SWIR; 1 to 2 µm). However, so far, there has been a fundamental limit: such quantum dots have relied on interband absorption of light (photons exciting carrier across the bandgap of the material). As a result, there is a lower energy limit that this technology cannot operate below: the bandgap of the material.

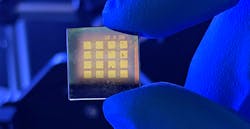

Now, researchers at ICFO, The Institute of Photonic Sciences (Barcelona, Spain), led by Gerasimos Konstantatos, report the development of a CQD photodetector that is capable of detecting light in the LWIR, using PbS CQDs that, for the first time, are made with mercury-free material.1The devices had responsivities on the order of 10-4 A/W at 80 K in the 5 to 9 µm range.

In their experiment, the researchers electronically doped the quantum dots robustly and permanently. This heavy doping approach allowed them to enable a new regime for transitions of electrons: instead of relying on transitions across the bandgap of the material, they found a way to facilitate transitions among higher excited states called intersubband (or intraband) transitions. By achieving this, they were able to excite electrons by absorbing photons with photon energies much lower than before in the MWIR and LWIR. They also demonstrated that the spectral coverage of such detectors can be tuned by changing the size of the dots—the larger the CQDs, the farther the absorption in the IR.

Source: https://www.icfo.es/newsroom/news/article/4594

REFERENCE:

1. Iñigo Ramiro et al., Nano Letters (2020); https://doi.org/10.1021/acs.nanolett.9b04130.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.