The display industry is quite broad, covering everything from materials to finished products for displays used in consumer, professional, and commercial applications. DisplayWeek, an annual conference organized by the Society for Information Display (SID), held a virtual conference this year that highlighted recent advances across the range of display technologies and applications. This article summarizes some of the key advances coming out of this conference, with a focus on what the major panel makers were showcasing. Panel makers are the ones that often innovate display technology, selling their products to brand companies that make the finished consumer and professional display-based products.

Liquid-crystal displays (LCDs) are the dominant display technology, having displaced nearly all competitors in a wide range of applications over the last two decades. Organic light-emitting displays (OLEDs) have recently gained wide acceptance in mobile phones and in the TV market. Direct-view light-emitting diode (LED) displays have a dominant share in large-area displays for signage or information. However, change continues at a rapid pace in all these major technologies.

For example, in LCDs, the trend has been to expand their color-gamut performance by incorporating new phosphors or quantum-dot technology. They have also expanded their contrast ratio to offer high dynamic range (HDR) capabilities to improve the rendering of darker shades and permit higher luminance for brighter objects. Higher resolution has been introduced, as 8K now tops the lines of all major TV brands.

OLEDs are self-emissive, so they don’t need a backlight the way LCDs do. Recent trends here have included the fabrication of OLEDs on thin and flexible substrates, as well as transparent display approaches. Actuators can be added to OLEDs as well to allow audio to emanate from the display rather than from separate speakers. New processing methods are also now enabling ink-jet printing of OLEDs, promising to reduce costs.

LEDs are inorganic emissive light sources. LED displays are composed by assembling red, green, and blue LEDs in a matrix configuration along with driver chips. These “cabinets” can be tiled together to make large displays of arbitrary size and shape for use in corporate lobbies, retail, and entertainment. Recent trends here include shrinking the size of the LED die to reduce costs and decreasing the pixel pitch to allow new applications with viewing at closer range.

Mobile displays

In mobile-phone displays, OLEDs are rapidly displacing LCDs due to their better performance. Samsung Display did not exhibit at DisplayWeek, but they are the clear leader in patterned RGB displays for mobile applications. In mobile phones, the trend is to increase screen-to-body ratios, eliminate the “notch” in the display screen, move to foldable and flexible screens, and continue to refine the integration of sensors and films within the display stack. Already, foldable phones are on the market from several manufacturers, as are phones that eliminate the notch and move the camera behind the display.

Chinese panel fab company BOE is now the largest display maker in the world and is competing in nearly all display technology areas. In mobile displays, for example, the company has developed a foldable OLED panel that is now used in the Huawei Mate XS mobile phone (see Fig. 1a). When folded it is a 6 in. screen, but unfolded it transforms into an 8 in. tablet.

At DisplayWeek, BOE debuted a prototype rollable 12.3 in. OLED display that operates like a Roman scroll (see Fig. 1b) and announced a new 6.4 in. phone display that can run at multiple refresh rates (30/60/90/120 Hz).

LG Display (LGD) is also active in foldable OLEDs; at DisplayWeek the company unveiled its new laptop design that is expected to be used in a Lenovo ThinkPad X1 later this year (see Fig. 2). The photo of the product is a bit misleading, as the keyboard is a display and the hinge is an image as well—that is, this is one continuous OLED panel from top to bottom. When the laptop closes, a small screen remains on at the edge to allow for notifications to appear. When fully open, the device become a tablet with a 13.3 in. screen. It is also the first device to support pen touch.Just before DisplayWeek, Taiwan-based display maker Innolux announced development of a 6.4 in. mobile-phone display with the camera embedded behind the screen—part of a trend toward larger screen-to-body ratios.

Gaming displays

One of the key areas of innovation in LCD displays is the move to mini- and microLEDs. These categories refer to the size of the LED emitting area, with miniLED generally having sides in the 100–300 μm range and microLED sized under 50 μm or so. MiniLEDs can mostly leverage the package and assembly techniques used for larger surface-mount device (SMD) LEDs used in backlights for LCDs and as direct-view LED screens. MicroLEDs require new processes and equipment development. The motivation to move to smaller LEDs is to reduce cost and improve performance. MiniLEDs are being targeted at automotive, gaming, and TV backlights as well as direct-view LED screens; microLEDs are targeting similar applications, but will lag in commercialization.

In gaming monitors, the trend has been to increase refresh rates, move to higher performing HDR technology, reduce lag time (time between an input and seeing the result on the screen), and offer ultrawide-aspect monitors in a curved form factor for a more immersive viewing experience.

At DisplayWeek, Taiwan-based panel maker AU Optronics (AUO) pushed the refresh rate parameter in their miniLED-based gaming display. Its new 17.3 in. laptop 1080p display developed with Nvidia becomes the first to offer a 300 Hz refresh rate with 1000 nits of HDR performance, while the 27 in. standalone version offers 240 Hz refresh rate. Upping the frame-rate ante, BOE revealed a new 360 Hz gaming panel at 15.6 in. and 1920 × 1080 resolution. BOE also showcased a 32:9 aspect ratio curved OLED 49 in. panel with a 240 Hz refresh rate that is aimed at gaming-monitor makers. Innolux added a 31.5 in. 4K miniLED HDR LCD display for monitor applications to its line.

Another exciting development is the coming commercialization of ink-jet-printed OLED displays, promising to reduce costs via more-efficient materials utilization. At DisplayWeek, AUO said it plans to commercialize one of the first ink-jet printed OLED displays as a 17.3 in. model with 4K resolution, 120 Hz refresh rate, and 100% coverage of the DCI-P3 color gamut. Just after DisplayWeek, Samsung Display announced it had developed an 18.2 in. printed OLED display with 2560 × 1440 resolution and 350 nits of full white luminance. However, the company stopped short of announcing commercialization, instead noting the much lower efficiency of the blue OLED printed material vs. materials made via the conventional vacuum-deposited method of fabrication.

TVs

One of the big uses of miniLEDs is in backlight units (BLUs) for TVs, where tens of thousands of miniLEDs replace hundreds of conventional LEDs. Why do this? The illumination of the backlight and the LCD panel are both modulated in response to the video signal. This double modulation dramatically increases the contrast and, by adding more or smaller LEDs at a higher density, more “zones” now exist to modulate. This enables less blooming or haloing around high-contrast areas (think moon on star background or credits on black background). The goal is to try to achieve the pixel-level high contrast offered by OLED displays.

China Star Optoelectronics Technology (CSOT) is the panel subsidiary under TCL, which offers a number of display-based consumer electronics products including TVs. At DisplayWeek, the company highlighted its miniLED BLU. CSOT noted that the manufacture of LED displays has historically placed them on printed circuit boards (PCBs) with passive-matrix driving. CSOT showed its miniLED BLU with active-matrix driving on a glass substrate. Its 8K resolution display features 20,763 miniLEDs and is offered by TCL as its Vidrian display technology.

AUO has developed a bezel-less 8K panel that is used in a Samsung Electronics TV (see Fig. 3); the bezel is so small (0.9 mm on three sides) that it essentially disappears. This high screen-to-body ratio is a popular trend in mobile phones, and it is now part of the TV vernacular as well.Samsung Display has also been a key innovator in developing quantum dot technology, mainly for TVs offered by Samsung Electronics. Quantum dots are nanometer-scale materials that are typically embedded in a film that absorbs light from a blue-LED backlight and converts some of this light to red and green. All three colors have narrow emission spectra, allowing displays to achieve the desired 100% of DCI-P3 color-gamut coverage. Quantum dot-based TVs from Samsung and others are branded as QLED TVs.

Meanwhile, BOE was talking about its ADS Pro LCD panels, which address some of the viewing-angle shortcomings of LCD technology, allowing the contrast and color accuracy to be extended to wider viewing angles. BOE has also developed a miniLED BLU. The company is developing these BLU modules to serve all the LCD consumer markets, plus medical and automotive. Already commercialized is a 75 in. 8K TV panel with more than 5000 dimmable zones and a 27 in. monitor with more than 1000 zones.

One of the more interesting additions to BOE’s LCD display portfolio is what it calls “BD Cell.” The idea is to replace the miniLED backlight unit with a second LCD panel. On the company’s 65 in. 4K resolution TV panel, the second panel has a 1920 × 1080 resolution, allowing 2 million dimmable zones—a big help in reducing halos, and also achieving OLED-like screen performance (its static contrast is 100,000:1). BOE announced a full range of BD Cell TV products at DisplayWeek, including 75 in. and 110 in. 8K TVs. The main customer for this is Hisense, who will bring these TVs to market.

Chinese fabs have made huge investments in LCD factories in China in the last several years. Seeing the writing on the wall, both LGD and Samsung Display are abandoning LCD manufacturing to focus on OLEDs and microLEDs. Samsung Display, for example, is now leveraging its QLED and OLED knowledge to offer a new category of display called quantum dot on OLED (QD-OLED).

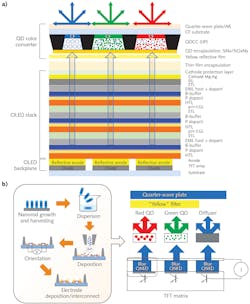

A QD-OLED display starts with a pixelated blue OLED display (see Fig. 4a). On top of this is a color-conversion layer composed of red and green quantum dots that are ink-jet printed at the subpixel level. The blue subpixel gets a light-dispersing material. A top color filter is needed as well to block room light (which has a blue component) from entering the display and activating the quantum dots.The blue OLED materials are what is used in OLED mobile displays and OLED TVs, but blue has the shortest lifetime and lowest efficiency, which is why Samsung is using a triple stack to increase both items. TVs using the QD-OLED approach could well be shown at CES 2021, with products commercially available sometime in 2021.

The second approach, called quantum nano-emitting diodes (QNEDs), replaces the blue OLED stack with blue nanorods (see Fig. 4b). Nanorods are a type of nanometer-scale microLED fabricated in gallium nitride (GaN)-based materials, but in the form of devices that are very tiny and have an unusual shape. As shown in the process-flow diagram, the nanorods are etched from a blue GaN epi wafer and placed in a liquid. They are then deposited using ink-jet printing on a backplane with driving circuits, which are then activated to attract the nanorods to each pixel location. This forms the blue light source with a similar top structure as the QD-OLED approach. QNED helps to overcome some of the potential issues with OLED blue materials, but it is a far less mature process so would likely be a replacement technology if perfected.

All OLED TVs have a white-light OLED layer composed of blue- and yellow-emitting stacks; red, green, and blue color filters are then needed to create a video image. Smaller OLED panels can directly deposit red, green, and blue materials, but this technology has not yet been extended to larger sizes, which is why Samsung Display is commercializing QD-OLED.

LGD highlighted its OLED panel technologies; rollable was a key theme (see Fig. 5). The company has shown 65 in. rollable TVs for over a year; LG Electronics says it will introduce this soon, but it is not yet available. This 4K resolution model can roll up or roll down, offering nice flexibility for the end user.Innolux is also working on a rollable display and recently unveiled a 55 in. LCD using a miniLED backlight. Note that this is not an OLED panel; rollable LCD displays are a much bigger challenge. Innolux did not reveal any details, however.

BOE has been working to develop a large area RGB OLED ink-jet-printing and has now revealed a prototype 55 in. 8K resolution display which the company unveiled for the first time at DisplayWeek. BOE plans to launch this along with 14, 17, and 30 in. printed OLEDs.

BOE also announced development of a prototype QD-OLED display at a 13.6 in. size, giving Samsung Display a little competition. BOE has not announced any commercialization plans for this technology, however.

Innolux will also try to entice TV makers to move beyond the conventional 16:9 TV format. It plans to make panels at 21:9, 24:9, 27:9 and 32:9, allowing the display of many types of additional information or interactive applications in the area to the side of a conventional 16:9 video image.

Outdoor TVs are coming too. Samsung already sells one, and Innolux will now offer a full water-resistant and sunproof TV with a sound bar and 2000 nits of luminance.

Automotive

AUO is also very focused on the automotive market, where more display real estate is a clear trend. Here, the company has developed two new microLED-based solutions. The first is a V-shaped instrument cluster composed of two 12.1 in. microLED displays (see Fig. 6a); this is not a backlight, but a self-emissive display with the microLEDs placed on a glass active-matrix backplane with the integrated drivers fabricated with low-temperature polysilicon (LTPS) technology.The second is an S-shaped curved display composed of two 9.4 in. flexible microLED displays developed in cooperation with PlayNitride (see Fig. 6b). One of the big challenges for moving microLED technology into mass production is the transfer of the red, green, and blue LEDs from their donor wafers to the final display substrate, be it printed circuit board (PCB), glass, or plastic. PlayNitride has developed a mass transfer process that can quickly transfer the 5.5 million 30-μm-diameter microLEDs to the backplane using a stamp-based technology. The company sees this display also targeted at wearable applications.

LGD used DisplayWeek to extend its rollable OLED theme to the automotive market with a new design that can be used for backseat entertainment, dashboard integration, sun visors, roof displays, center console augmentation, and more (see Fig. 7). It is a 12.8 in. screen with 1888 × 1728 resolution. LGD has also developed a curved cockpit display concept composed of two flexible OLED panels.AR/VR

BOE is a player in the augmented-reality/virtual-reality (AR/VR) segments. For AR, BOE has developed an OLED-on-silicon microdisplay with very high pixel density (3100 PPI) and 1000 nits of luminance. The company even offers an eyeglasses-based design with a 52° field of view. In VR, the solution is a 3.5 in. 4K × 4K BD cell device.

For AR, LGD showed an OLED-on-silicon microdisplay offering 4000 nits of luminance and 3500 PPI in a 0.42 in. package.

Other display trends

AUO is taking its miniLED technology to other high-value markets. For example, the company announced new 32 in. medical monitors for laparoscopic and endoscopic surgery and a 21.3 in. portrait display for radiation medicine and mammography applications. The 32 in. display has augmented red color capabilities specifically requested by the surgical community.

Many smaller markets also like to have custom-shaped displays, but the tooling for such displays can be expensive. As a result, cutting the desired shape from a larger display or bonding two smaller displays have emerged as cost-effective options. CSOT showcased an 86 in. display with touchscreen capabilities that is constructed by bonding two smaller LCD panels together to create an extra wide aspect ratio display (32:9). The gap is 12 mm, which will be visible when viewed at close distance.

AUO’s TARTAN display tech is designed to allow creation of specialized display panels by creating customized masks to make these panels natively instead of cutting larger panels or joining smaller panels. At DisplayWeek, it debuted the largest round LCD display at 23.6 in. diameter.

For professional use applications, CSOT has developed a 105 in. LCD model with highly accurate touch capabilities (±2.5 mm) and fast response for multiuser interactive whiteboarding.

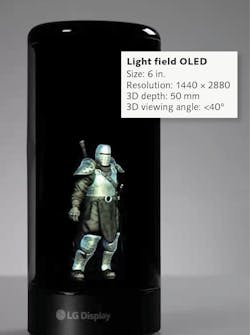

LGD talked about its large-sized transparent OLEDs. These can be used for retail, museums, and art galleries and even on luxury aircraft or automobiles. Just after DisplayWeek, LGD announced that it is providing the first transparent OLED screens for subway cars in Beijing and Shenzhen, China.Finally, LGD has developed a 6 in. light-field display that creates a 3D image inside a smart speaker (see Fig. 8). In reality, this is not a real light-field display, but a multiview horizontal-parallax autostereoscopic display.

About the Author

Chris Chinnock

Chris Chinnock is president and owner of Insight Media in Norwalk, CT. He is a 30-year display industry veteran with experiences in displays, broadcast, cinema, ProAV, and consumer electronics.