Partnership to develop deep-cooled SWIR camera for research uses

Lytid (Paris, France) has released its SIRIS shortwave-infrared (SWIR) camera, a deep-cooled SWIR camera based upon a Lin/Log indium gallium arsenide (InGaAs) sensor from New Imaging Technologies (NIT; Verrières le Buisson, France) and image processing algorithms from the French National Centre for Scientific Research (CNRS; also in Paris).

SIRIS exhibits readout noise <10 e- and dynamic range >120 dB simultaneously because of NIT’s Lin/Log 1601 SWIR sensor. The camera is deep-cooled down to 50 K with a long-life cryocooler, allowing a drastic reduction of dark current. Exposure time over one hour can be easily obtained. Everything is fully integrated into a compact and plug-and-play casing based on Lytid’s advanced photonic system integration.Moreover, the camera incorporates advanced noise reduction algorithms developed by ENS-CNRS, among which nondestructive readout noise reduction is embedded. The resulting noise performance is drastically reduced and the final readout noise is less than 10 e-.

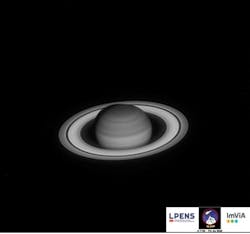

Applications for the camera cover high-end imaging such as astronomical research, biomedical imaging, and bioluminescence.