Reality is changing. School, work, even doctor visits can happen today without leaving home. Technology needs to keep pace with today’s ever-changing world, so continuous progress is crucial.

The future of laptops, smartphones, and now automobiles relies, in part, on advances in displays. And the market is growing, with an estimated value of $186 billion globally by 2023.

During the next several years, experts predict a nearly 4% compound annual growth rate (CAGR), citing various driving factors: the surging adoption of organic light-emitting diode (OLED) displays expanding use of LED displays for things like “video walls, TVs, and digital signage applications, a growing demand for interactive displays, and rising demand for display-based medical equipment, including ventilators and respirators.”

OLED displays

Researchers at the University of Minnesota, Twin Cities have developed a 3D-printed, flexible OLED display—the first of its kind. Its introduction could pave the way for lower-cost displays “that could be widely produced using 3D printers by anyone at home, instead of by technicians in expensive microfabrication facilities.”

Their study, published in Science Advances, says OLEDs are competitive alternatives to liquid crystal displays (LCDs)—the current standard for flat-screen TV screens. OLEDs tout self-emission and higher contrast ratios than LCDs, as well as fuller viewing angles, higher power efficiency, and mechanical flexibility.

This new technology is based on the conversion of electricity into light using an organic material layer, which allows OLEDs to be high-quality flexible digital displays for use in TV screens and monitors as well as smartphones and other smaller, handheld devices. Such displays, the researchers note, are also lightweight, more power-efficient, and thin. Producing them, however, is challenging because OLED displays are typically manufactured in large, expensive fabrication facilities.

“We wanted to see if we could basically condense all of that down and print an OLED display on our tabletop 3D printer,” says Michael McAlpine, a professor in The University of Minnesota’s Department of Mechanical Engineering.

Among initial obstacles with the 3D printing process was with nonuniformity of extrusion-printed active light-emitting layers. The researchers describe the creation of repeatable and stable polymer-metal junctions between the active layer and the cathode using the 3D printing approach at room temperature as “difficult.”

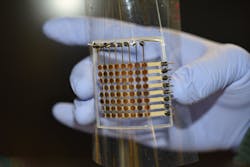

The OLED display comprises six device layers created by combining two different modes of printing. Extrusion printing enabled researchers to overcome issues relating to printability, electrodes, interconnects, insulation, and encapsulation—the active layers were then spray-printed using the same 3D printer at room temperature. The display prototype measured 1.5 in. on each side, and 64 pixels of light (see Fig. 1).

“The device exhibits a relatively stable emission over 2000 bending cycles,” says Ruitao Su, who earned a Ph.D. from the university and is now a postdoctoral researcher at MIT. He notes the displays could be packaged in an encapsulating material, opening up a variety of potential applications such as wearable displays. And the entire fully 3D-printed process could prompt “futuristic concepts” including displays “interwoven with soft robotics for electroluminescent body parts and three-dimensionally structured pixel matrices for holography.”

A team in South Korea is also exploring the use of OLEDs for advanced displays. In work published by Springer—Advanced Display Technology: Next-Generation Self-Emitting Displays—authors Byeong Kang, Ph.D. (former CTO of LG Display, Korea and a fellow of The Society for Information Display); Chang Wook Han, Ph.D. (a chief research fellow and VP at LG Display); and Jae Kyeong Jeong, Ph.D. (a professor in the Department of Electronic Engineering at Hanyang University (Seoul, South Korea) and a member of the Scientific Reports and Journal of Information Display editorial board) report: “OLEDs today can be manufactured at 8K resolution on a large scale, and with remarkable efficiencies, color purity, and long lifetimes.”

Many of the imaginative possibilities for OLED technologies are finding their way into commercial devices, they say, including foldable devices, transparent displays, and rollable televisions.

OLED displays are also boosting smartphones. Companies including Samsung and Motorola have already rolled out smartphones with flexible screens. The IEEE Computer Society says this “new breed called ‘flexphones’ feature flexible substrates, unique materials, and ultrathin displays that can be folded multiple times without creasing.” Nearly all flexphones feature OLED displays (see Fig. 2).Sri Peruvemba, CEO of Marketer International Inc. (California) and board director of Summit Wireless Technologies Inc. (San Jose, CA), notes foldable phones will ultimately become even thinner and feature a longer battery life.

Micro-OLEDs have the potential to bring augmented reality/virtual reality (AR/VR) technology to the next level. Unlike LCD displays, and even OLED displays, micro-OLED screens are directly mounted to single crystal silicon wafers, enabling the production of thinner, more power-efficient, self-illuminating displays. This suits AR/VR wearable technology, according to TechNews, a source used by technology companies worldwide.

Companies including Apple, Sony, and Samsung are currently developing displays featuring micro-OLEDs.

Smart glass displays

Also called switchable glass, smart glass touts light transmission properties that are altered when voltage, light, or heat is applied. It can also alternate between transparent and opaque, and is now finding applications in marketing and advertising. When opaque, the smart glass display acts as a projection screen on a traditional glass storefront. When transparent, it features that same type of display but allows an unobstructed view into the store.

Smart glass has proven ideal for privacy in homes (bathroom and bedroom windows as well, and other settings such as hospitals.

Autonomous vehicles

The automotive smart display market is booming. By 2025, it’s expected to reach $10.9 billion, increasing at a CAGR of nearly 10%. Global market analysts Research and Markets attribute such growth to the advancement of autonomous vehicles.

Smart displays used in autonomous vehicles are referred to as head-up displays (HUDs). Karlheinz Blankenbach, a professor at Pforzheim University (Germany) and founder of the school’s Display Lab, discussed the future of this technology at this year’s SPIE Photonics West.“Autonomous cars should communicate by exterior displays with other road users to increase safety,” he says. Such displays can show information such as visualization of the vehicle’s driving mode, the current speed limit, visual detection of other vehicles and nearby pedestrians, and navigation instructions (see Fig. 3). He and his Display Lab team note there are ongoing challenges in implementing this technology into vehicle designs, given their current novelty, but they’re continuing their research.

Justine Murphy | Multimedia Director, Digital Infrastructure

Justine Murphy is the multimedia director for Endeavor Business Media's Digital Infrastructure Group. She is a multiple award-winning writer and editor with more 20 years of experience in newspaper publishing as well as public relations, marketing, and communications. For nearly 10 years, she has covered all facets of the optics and photonics industry as an editor, writer, web news anchor, and podcast host for an internationally reaching magazine publishing company. Her work has earned accolades from the New England Press Association as well as the SIIA/Jesse H. Neal Awards. She received a B.A. from the Massachusetts College of Liberal Arts.