Ultrafast science at the atomic and molecular levels

X-ray free-electron lasers such as the SwissFEL (located at Switzerland’s Paul Scherrer Institute) are opening completely new dimensions to researchers. By generating extremely short, intense flashes of x-ray light, these lasers can now map processes previously much too fast for experiments. As a result, numerous biological and chemical processes are being recorded for the first time.

Monitoring electron beams is crucial to the successful operation of the SwissFEL. The cameras selected for this task are scientific CMOS (sCMOS) cameras, including the pco.edge 5.5 CLHS, which not only delivers brilliant images thanks to its low-noise sensor, but also transmits the images over the required long distance at a high data-transfer rate using Camera Link HS (CLHS) technology.1

Electron accelerators as light sources

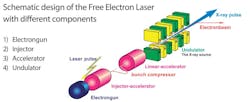

SwissFEL consists of four parts: an injector with an electron source, the linear accelerator, an array of undulators, and experimental equipment (see Fig. 1).2

The Paul Scherrer Institute compacts and stabilizes the electron source to enable a cost-efficient setup. A pulsed UV laser releases the electron beam from the cesium telluride photocathode, and timing of the laser pulse is synchronized to the radio frequency of the cavity in which it is placed. This specially shaped chamber contains an electric field that accelerates the emitted electrons via a standing wave to almost the speed of light. This acceleration generates a magnetic field that inhibits the tendency of the electrons to disperse.

After the initial acceleration, the electron bunch flies toward the linear accelerator (LINAC), a 400 m straight line consisting of 104 high-accelerator structures, to further boost its energy. Along the path of the LINAC, already-short electron bunches are compressed further in the longitudinal direction via bunch compressors. In the process, the electrons pass through a chicane of four strong magnets to force the first electrons onto a longer path and the last electrons onto a shorter one until their final distance from one another is in the femtosecond range.3

With a final energy of 6 gigaelectron volts (GeV), the electrons are moving fast enough to be split by a magnetic switching system to simultaneously supply two different undulator lines: the hard x-ray undulator line (ARAMIS) and the soft x-ray undulator line (ATHOS). The undulators are special alternately poled magnetic arrays that send the electrons on wave-like paths. This movement of the electrons leads to intense, coherent x-ray pulses needed for research. After the x-ray beam exits, unneeded electrons are diverted, and the x-ray beam is forwarded to the respective experimental station.4

The wavelength of the light should correspond to the size of the structure to be examined. The wavelength of visible light is much too long, but x-ray light is perfect for atomic structures. The achievable time scales of the x-ray light pulses are so short (femtosecond time scale) and the light so intense they can be used to observe the movement of atoms and molecules, which enables researchers to study processes that were previously much too fast.

New insights for science, medicine, technology

Researchers at Paul Scherrer Institute’s various experimental stations come from many different fields of science. At one of these experimental stations, for example, it is possible to study molecular dynamics and reactivity in solution and in heterogeneous catalysis. Step by step, researchers can follow how the smallest building blocks of a substance separate from one another in a chemical reaction and then come together to form a new substance. For other observation methods, these processes are much too fast. But the extremely short flashes of SwissFEL make it possible to image the individual, intermediate steps with short exposure times. A precise understanding of these reactions can help to optimize processes in the chemical industry, making them more cost-effective or resource-efficient.

Intelligent drug design requires detailed knowledge of the relevant biochemical system, such as proteins, preferably in the form of a 3D-molecular structure at atomic resolution. Correct arrangement of the atoms is crucial for such molecules, which typically comprise tens of thousands of atoms, to function properly. Until recently, x-ray crystallography required the use of large, well-diffracting crystals to limit radiation exposure when determining the atomic and molecular structure of a specimen. But these crystals were often difficult or even impossible to produce. With the femtosecond x-ray flashes from SwissFEL, only very small crystals are needed. These ultrafast snapshots overcome the effects of radiation damage, because diffraction data can be recorded before radiation damage can destroy the specimen.

Knowledge gained from experiments at the institute could lead to new classes of materials, such as quantum spin liquids, topological insulators, and new superconductors. Results from institutes such as SwissFEL are essential to exploit the large potential of these fascinating materials.5

High data rates over long distances

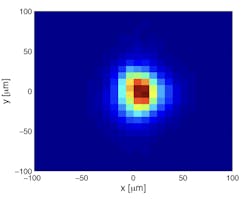

The operation of a FEL requires strict control of the energy spread of the electrons. Too large of an energy spread in the undulator hinders the FEL process. Bunch lengths that are too small may interrupt the beam if a part of the spectrum is dominated by coherent emission of synchrotron radiation in the bunch compression chicanes. Especially recent developments toward the highest brilliance x-rays and subfemtosecond pulse lengths are leading to more stringent requirements on this instrumentation.6In the bunch compressors, scintillation screens in the path of the dispersed electron beam measure the energy distribution. The sCMOS camera (pco.edge 5.5 CLHS) records spectral profiles of the electron beam pulses at high sensitivity (100 fps) and, in conjunction with a 300 mm lens, can resolve beam profiles with a projected pixel size of 0.04 mm (see Fig. 2). Since this detection method is completely nondestructive, it is used for routine monitoring of the beam energy and energy propagation, as well as optimizing the beam compression configuration. The camera also enables precise measurement of the energy distribution in the injector and undulator beamlines (see Figs. 3 and 4).7

The Fiber Optic Link provides high resistance to electromagnetic interference (EMI). Conversely, the fiber does not radiate emission, which can interfere with other systems.8 Also, long distances between the camera and PC can be realized without technical obstacles. The specialized CLHS X protocol compensates for any trigger-command delay, ensuring additional trigger jitter over the cable is extremely low or nonexistent, depending on how the receive path for the link is implemented. Besides offering distance and high data throughput, a fiber cable is also advantageous in terms of price, and the hardware is based on standard network components. Finally, CLHS is fully compliant with the GenICam specification defined by the EMVA (European Machine Vision Association). For this reason, experts are convinced that CLHS technology will also be the interface of choice in the future.

A perfect place for future cutting-edge science

SwissFEL researchers have not come close to reaching the limit, and further enhancements of the design are possible. Control of the electron bunches via the properties of the laser and the accelerator will enable further FEL modes in the future, including the generation of single or trains of sub-femtosecond FEL pulses, multicolor FEL pulses, and the generation of fully coherent x-ray pulses by laser-based seeding. In this way, cutting-edge research will continue to be possible in the future, and their next experiments are already in the pipeline.9

REFERENCES

1. See www.automate.org/a3-content/vision-standards-camera-link-hs.

2. See www.psi.ch/en/swissfel/how-it-works.

3. See www.mdpi.com/2076-3417/7/7/720.

4. See https://accelconf.web.cern.ch/ibic2013/papers/tupf08.pdf5.

6. R. Ischebeck, E. Prat, V. Thominet, and C. O. Loch, Phys. Rev. ST Accel. Beams, 18, 082802 (Aug. 27, 2015); http://dx.doi.org/10.1103/physrevstab.18.082802.

7. T. Schietinger et al., Phys. Rev. Accel. Beams, 19, 100702 (Oct. 26, 2016); http://dx.doi.org/10.1103/PhysRevAccelBeams.19.100702.

8. See https://accelconf.web.cern.ch/FEL2014/papers/thp098.pdf.

Franziska Naporra | Application Specialist & Product Manager, Excelitas PCO

Dr. Franziska Naporra is application specialist & product manager at Excelitas PCO (Kelheim, Germany).

Martin Schwarzbauer | Manager Camera Systems, Excelitas PCO

Martin Schwarzbauer is manager of camera systems (product development) at Excelitas PCO (Kelheim, Germany).

![FIGURE 3. Example of a beam-profile imager with the pco.edge 5.5 CLHS [7]. FIGURE 3. Example of a beam-profile imager with the pco.edge 5.5 CLHS [7].](https://img.laserfocusworld.com/files/base/ebm/lfw/image/2022/07/fig3.62ded01147f1a.png?auto=format,compress&fit=max&q=45&w=250&width=250)

![FIGURE 4. Twenty-seven transverse beam profile imagers are installed in SwissFEL for routine monitoring [7]. FIGURE 4. Twenty-seven transverse beam profile imagers are installed in SwissFEL for routine monitoring [7].](https://img.laserfocusworld.com/files/base/ebm/lfw/image/2022/07/fig4.62ded03e9de83.png?auto=format,compress&fit=max&q=45&w=250&width=250)