Miles J. Weida, David Arnone, and Timothy Day

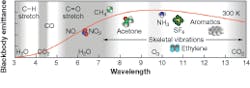

The utility of mid-IR (3 to 12 μm) radiation for identifying molecules has long been known. Most molecular bonds have strong absorptions and emissions in this region at very specific frequencies. Researchers have shown that these mid-IR fingerprints can be used in a wide variety of chemical detection and imaging applications (see Fig. 1).1, 2 So why aren’t devices using the mid-IR common in everyday applications?

The answer is that technologies using the mid-IR have been expensive and cumbersome. Only in the past five years have mid-IR detectors advanced to the point that sensitive point and array detectors can operate at room temperature. The state of mid-IR generation is even more problematic. Current technologies for producing tunable mid-IR radiation are esoteric (for example, synchrotrons or free-electron lasers), difficult (cryogenically cooled lead-salt diodes), or expensive (for example, multiple-laser difference-frequency generation). Moreover, many of these technologies produce limited amounts of laser power. Broadly tunable mid-IR sources suitable for mass-produced commercial products simply have not been available.

Because of these barriers, the only viable technology for commercial mid-IR chemical detection and imaging has been Fourier-transform IR (FTIR) spectroscopy-a technique lacking in speed, sensitivity, and the potential for commercialization.

Enter the quantum-cascade laser

The invention of the quantum-cascade (QC) laser in the 1990s changed the landscape for mid-IR radiation generation.3 Increasingly sophisticated material-growth technologies coupled with computational simulations have made it possible to design and grow devices that can lase throughout the mid-IR. Quantum-cascade materials are unique in that the planned growth pattern of the device dictates the final lasing wavelength, as opposed to the intrinsic physical properties of the underlying material.

As QC technology has progressed, these lasers have become the heir apparent for mid-IR radiation generation. Room-temperature continuous-wave (CW) operation has been achieved for these devices, complementing the room-temperature operation recently achieved for mid-IR detectors.4 Standard metal-organic chemical-vapor deposition (MOCVD) techniques can mass-produce thousands of QC chips for commercial applications.5 Peak pulse powers of several hundred milliwatts are routinely achieved in our labs; QC devices will therefore be able to provide enough power to support even remote sensing and stand-off detection applications.

Conventional QC lasers, however, are at most only narrowly tunable. Frequency selectivity has been achieved by building a distributed-feedback (DFB) structure into the chip itself. These DFB QC lasers provide single-wavelength solutions, much like mid-IR gas lasers, and must be cooled to cryogenic temperatures to obtain even small degrees of tuning. The QC chip in and of itself still does not provide a broadly tunable laser for the mid-IR.

Broad tunability will enhance optical sensing

Daylight Solutions has developed a broadly tunable QC laser that has high potential for optical sensing. The technology is in part an outgrowth of technology developed for telecommunications diode lasers.

By applying an antireflection coating to one laser facet, telecom researchers incorporated a near-IR diode as the gain medium in a cavity containing a diffraction grating. Rotation and translation of the grating-enabled CW, mode-hop-free tuning over a significant percentage of the center wavelength. But significant technical challenges remained before external-cavity (EC) lasers could be reliably manufactured to meet the needs of the telecommunications industry. Research and development at New Focus (San Jose, CA), among others, resulted in the miniaturization and packaging techniques that enabled tunable near-IR lasers to be used in commercial applications.6

The lessons learned in telecommunications should have direct bearing on tunable mid-IR development with QC chips. In fact, it has already been demonstrated that QC gain media work extremely well in an EC laser with grating feedback.7, 8 Tuning ranges of up to 15% of center wavelength have been achieved.

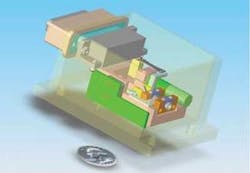

We have developed miniature components suitable for the mid-IR to mimic those found in near-IR EC lasers. These have been incorporated into a small commercial package (see Fig. 2). The miniature size of this assembly enables robust performance of an EC-QC laser (EC-QCL) under field conditions. To mitigate the effects of vibration and temperature change, careful engineering has reduced the size of the laser cavity and associated optomechanical components.The performance of the new EC-QCLs is far superior to tunable lead-salt diode lasers in the mid-IR (a traditional tunable mid-IR source for optical sensing). First, the unit operates at room temperature. Coupled with a room-temperature mercury cadmium telluride detector, or a vanadium oxide (VOX) microbolometer array, it is now possible to do mid-IR experiments with no cryogenic cooling. Researchers can bid farewell to liquid-nitrogen Dewars.

Second, the laser can be easily and repeatably tuned. With a center wavelength of 8.6 μm, the prototype laser demonstrates a tuning range of 8% of the center wavelength, with a step resolution of 0.01 cm-1. Even finer tuning resolution can be achieved via small current or temperature changes.

Third, EC-QCLs can deliver large amounts of power. In pulsed mode, the prototype laser delivers well over 200 mW of peak power over the entire tuning range for modest operating conditions. For longer duty cycles, average powers of more than 50 mW have been obtained.

Chemical detection

The performance and size of these tunable lasers should enable a whole new family of commercial products using the mid- to long-wave IR for chemical detection and imaging. As an example, many industrial processes involving gas delivery and manufacture can benefit from the commercialization of laser-based trace-gas sensing. Industrial gases such as water vapor, sulfur hexafluoride, ammonia, and many hydrocarbons are extremely important to monitor. Methane, ethylene, and propylene need to be monitored in the research and development of new combustion engines.

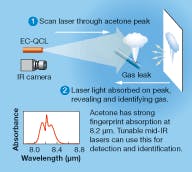

Industrial gases such as these can be monitored in a portable and commercially viable manner using tunable lasers together with long-wave-IR cameras (see Fig. 3). A 2-D imaging camera with high sensitivity at 8 μm is configured to image the beam that propagates through the acetone vapor. The camera and laser could be integrated into one module; the image would be of the laser beam as it transmits through the vapor to an object beyond the gas and back to the camera (traveling through the vapor a second time). As the laser is tuned from outside the absorption peak (approximately 8.0 μm) to the center of the absorption peak (approximately 8.2 μm), the laser beam would undergo strong absorption and cast a high-contrast shadow onto the 2-D imaging array. A fast scan of the laser together with high-speed image acquisition would allow the user to identify the vapor as the camera is scanned around the industrial plant. The laser could also be fixed at a wavelength of 8.2 μm and the entire module, as a handheld unit, scanned across the room. As the camera intercepted and imaged a fugitive emission, its shadow would be cast on the array; image-capture software would identify the leak.Molecular detection and imaging using tunable lasers and cameras in the mid- to long-wave IR can be used for many applications. Combustion diagnostics, pharmaceutical process control, hyperspectral imaging, cellular imaging, and explosives detection are just a few examples. The advent of commercially viable miniature tunable lasers in the mid- and long-wave IR will open up many economically important applications of optical sensing.

REFERENCES

1. A.A. Kosterev and F. K. Tittel, IEEE J. Quant.Electronics 38(6) 582 (2002).

2. M. Diem et al., Analyst 129, 880 (2004).

3. C. Gmachl et al., Rep. Prog. Phys. 64, 1553 (2001).

4. J. Piotrowski, Opto-Electron. Rev. 12(1), 111 (2004).

5. M. Troccoli et al., Applied Phys. Lett. 85(24), 5842 (2004).

6. T. Day, et al., Proc. SPIE 2378 (1995).

7. R. Maulini et al., Applied Phys. Lett. 84(10), 1659 (2004).

8. G. Wysocki et al., Applied Physics B: Photophysics and Laser Chemistry 81, 769 (2005).

MILES J. WEIDA is senior scientist, DAVID ARNONE is senior mechanical engineer, and TIMOTHY DAY is CEO at Daylight Solutions, Inc., 13029 Danielson St., Poway, CA 92064; e-mail: [email protected].