For light-based detection and identification of common substances, the mid-IR spectral band is all-important. Most common molecules have vibrational modes in this spectral region-modes that produce spectral-absorption peaks that can uniquely identify the substance, whether it is an illicit drug, a type of cancer, or an industrial chemical. The dual development of quantum-cascade lasers and room-temperature mid-IR detectors has brought practical mid-IR chemical detection within reach.

What is needed, however, is a light source that is broadly tunable, enabling spectral-absorption scans that span not just one narrow spectral peak, but a wide band. In this way, one light source can be used to detect many substances, or many spectral lines from one substance. Engineers at Daylight Solutions have developed just this source-an external-cavity tunable room-temperature QC laser-and are bringing it into commercial production.

While other tunable QC lasers have been around for years, they are based on temperature tuning of a distributed-feedback structure in the laser waveguide, and thus have a narrow tuning range (on the order of 10 cm-1, which, for a 9-µm emission wavelength, translates to about 0.08 µm). The new external-cavity laser, in one version, can be tuned from 8.25 to 8.85 µm; other versions have center wavelengths from 4.5 to 11.0 µm with ±5% tunability.

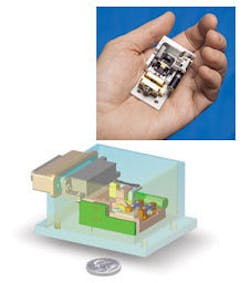

A key ingredient to the patent-pending laser is the pair of miniature aspheric lenses that help form the external cavity. Made of chalcogenide glass, the lenses have focal lengths that are less than 2 mm, making it possible to form an optical cavity only 25 mm long. The engineers at Daylight Solutions have developed lenses—both molded and diamond-turned—using several materials, says Tim Day, the company’s CEO and CTO. All can be manufactured in volume, and all offer diffraction-limited performance, which is required for the laser. The multilayer antireflection coatings are based on rugged refractory oxides and have a reflectivity of less than 1%.

Day notes that his engineering team is experienced in volume-manufacturing techniques; while at New Focus (San Jose, CA), the team members worked on the Intel (Santa Clara, CA) tunable telecommunications laser. “We have seen every tunable out there,” he says. The team is prepared to deliver on the order of tens of thousands of the tunable QC lasers per month in the future.

Applications for the laser include monitoring carbon monoxide and carbon dioxide in the 4- to 5-µm region for breath diagnostics; monitoring ammonia (NH3) for industrial, medical, and explosives sensing in the 8.5- to 10.5‑µm region (different center wavelengths could be chosen for different NH3 sensing needs); glucose sensing and detection near 9.5 µm; cellular imaging at 6 µm; and fugitive-emissions detection in the 8- to 11-µm region.

“We have seen significant commercial interest in this,” says Day. “We’ve already landed orders and programs to develop the laser for three key markets—biomolecules, breath biomarkers, and industrial sensors.”