Position-sensing detectors fill photonics test and measurement needs

Among the many types of photodetector configurations available for use by lab experimenters or optical systems developers is one that is especially useful for gleaning information about the alignment of laser and other optical setups: the position-sensing detector (PSD). As is clear from its name, the normal use of a PSD is for measuring the position of a light spot of some sort that falls on the detector.

This simple function is actually at the center of many test and measurement instruments and applications, ranging from beam alignment to adaptive-optical wavefront-shape measurement (in the form of a Shack-Hartmann wavefront sensor, which in some configurations can be based on an array of PSDs) and much more.

Depending on its configuration, a PSD can measure the movement of a spot in either one or two dimensions. One form of PSD consists of either two (bi-cell) or four (quadrant cell, or quad cell) discrete detectors, with the bi-cell and the quad cell able to sense the position of a light spot in one or two dimensions, respectively.

For a bi-cell, a normalized spot-position output can be determined by dividing the difference between the two cell outputs by the sum of the two cell outputs. For a quad cell, the quadrant outputs can be summed in two different ways to imitate two orthogonal bi-cells. The normalized spot-position in each direction can then be determined in a way similar to that for the imitated bi-cell.

A second form of PSD consists of a single continuous detector that senses spot position in either 1D or 2D based on the "lateral effect." (A third form of spot-position measurement not covered in this article is the use of a CCD, CMOS, or other type of camera to capture a spot image, along with the use of software to determine the position of the spot's centroid.)

Lateral-effect PSDs

As Dennis Popov, applications engineer at OSI Optoelectronics (Hawthorne, CA) explains, lateral-effect PSDs are continuous, single-element, planar-diffused photodiodes with no gaps or dead areas. These types of PSDs provide direct readout of a light spot displacement across the entire area. This is achieved by providing an analog output directly proportional to both the position and intensity of a light spot present on the detector active area.

"The main advantage of using these lateral-effect diodes is their wide dynamic range," Popov says. "They are independent of the light-spot profile and intensity distribution and provide position resolution better than 0.5 μm. The lateral-effect diodes measure the light spot position all the way to the edge of the sensor. These accuracies are achieved with two separate resistive layers, one located on the top and one located on the bottom of the chip. These detectors feature high reliability, wide dynamic range, and exhibit high linearity."

Popov notes that OSI manufactures one of the larger 2D lateral-effect sensing devices in the marketplace, the DL-20 (see Fig. 1), which is a 20 × 20 mm square device (400 mm2 position-sensing area). "Its wide dynamic range allows it to be used in many applications such as high-speed optical digital tracking systems," Popov says. "These have also have been used for human motion tracking for health rehabilitation purposes. These devices have a ruggedized package capable of being used in military and aerospace applications as well."

Other applications of these devices, according to Popov, include human eye movement monitoring, 3D modeling of human motion, and laser, light source, and mirror alignment. "They are also widely used in ultrafast, accurate autofocusing schemes for a variety of optical systems, such as microscopes, machine tool alignment, vibration analysis, and more," he adds.

Quad cells, both conventional and thermopile

Newport (Irvine, CA) produces both quad-cell and lateral-effect PSDs, including the lateral-effect-sensor based OBP series and CONEX-PSD series, and the quad-cell-based 2901 and 2903 PSDs from New Focus, which is a subbrand of Newport, as noted by Jay Jeong, senior product manager at Newport.

In addition, Newport makes thermopile-based quad-cell position sensors (the PEP series). A thermopile consists of a heat-absorbing disk with thermocouples placed around it to measure the voltage differentials created because of the heat absorption by the disk, Jeong explains. The thermocouples are divided into four different sides and the lead connected to each thermocouple section collects the voltage signal, which is equivalent to the current signal generated by a conventional quad-cell detector.

"Each of the products Newport offers have a different set of specifications, and the target applications are different," Jeong says. "The position sensors are used primarily for tracking beam drift or movement, fast or slow, and in a control system to correct the beam to a desired path or to minimize the beam movement. Due to the variety of beam characteristics, such as continuous-wave (CW), pulsed, or modulated laser sources, and the speed and amount of beam movement, in addition to the typical specifications including the output power level, size of the beam, intensity profile of the beam, and ambient noise level, one product cannot be used in all possible applications."

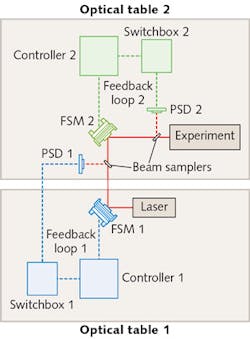

Jeong mentions the model OBP-U-9H, which is one of Newport's lateral-effect PSDs, as a product that has specifications and features able to meet many challenging applications. The device has a position accuracy of ±15 μm with a better-than ±1 μm resolution, he says. "The detector can accurately track the position of a laser beam with as low as 1 W, while the response time is shorter than 60 s through the analog output," he notes. "A high-power laser beam can be accommodated by installing stackable neutral-density filters." The PSD is equipped with a trigger input to handle pulsed laser sources, while its user interface simultaneously shows position, optical power, and charting and plotting of position and power over time via USB (see Fig. 2).As an example PSD application, Jeong describes a situation in which an experiment must be carried out on two separate optical tables for reasons such as space limitations, and/or the isolation and decoupling of certain vibrations induced by a component used in the experiment; at the same time, the beam must be maintained in a constant path.

"When one of the optical tables suddenly moves due to bumping by an experimenter or vibrations from an instrument or equipment, the mirrors need to quickly adjust to establish the beam path," Jeong says. An active beam stabilization setup can be used to accomplish this (see Fig. 3). The first detector, PSD1, provides the position feedback to the first controller to correct the beam position by controlling a fast steering mirror (FSM1). The second set, PSD2 and FSM2, fine-tunes the beam path so that the beam enters the experiment along the desired path.Pyroelectric quad-cell position detection

A thermal quad-cell PSD produced by Gentec Electro-Optics (Québec City, QC, Canada) is based on pyroelectric detection, according to Don Dooley, general manager at Gentec Electro-Optics USA (Lake Oswego, OR), who notes the detectors are made by depositing an absorbing front electrode on a pyroelectric wafer that is patterned in a quad configuration using a photolithography technique. "These are large area, broadband, thermal detectors that can be used with either pulsed or CW sources across the spectrum from 0.19 through 10.6 μm, and even terahertz (30-3000 μm)," he says. "They range in size from 9 mm diameter to 20 mm square. Unlike quadrant or lateral effect silicon photodiodes, pyroelectric detectors do not suffer from photocurrent saturation. This makes them an ideal choice for high peak power pulsed lasers."

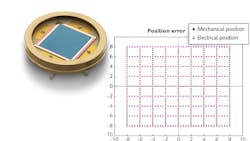

As examples, Dooley mentions Gentec's QUAD-9-MT-E and QUAD- 4TRACK detector and monitor, respectively. "The QUAD-9-MT-E is a 9-mm-diameter quad detector (see Fig. 4) mated to a four-channel preamplifier that is designed for use with pulsed lasers with pulse lengths from femtoseconds to microseconds," he explains. "It integrates the voltage output of the four detectors and is calibrated in volts per joule. When attached to our QUAD-4TRACK digital monitor, you can measure both position and energy simultaneously. The laser pulse energy must be at least 50 μJ and no more than 20 mJ. The QUAD system can track position at up to 1000 pulses per second and to a resolution of a few microns." Laser applications include alignment, tracking, beam centering, beam steering measurement, and spatial stability."One interesting application is the use of this detector/monitor combination within a carbon dioxide (CO2)-laser-based robotic welding system," Dooley says. "Our quad detector is used to center the laser beam in the articulated optical delivery arm after it has moved to several weld locations. It's working all the time on the fly and helps guarantee that the welds are placed accurately on an automobile frame."

1D measurement

Applications in which 1D detection is desired (for example, measuring interference-fringe movement1) can use the simpler 1D PSDs, either lateral-effect or bi-cell. An example of a type of lateral-effect 1D PSD that takes advantage of technology specific to 1D PSDs is a line of so-called "NT" 1D devices made by SiTek Electro-Optics (Partille, Sweden). SiTek's 1D PSDs with NT technology contain a form of inherent stray-light elimination, in the form of an extra electrical terminal on the front side that is connected to an extra active area on the PSD that senses the stray light-when connected to ground, the extra terminal automatically eliminates the signal from the stray light. Uses of these PSDs include height and thickness measurement, wheel alignment, profile measurements, and inspection of manufactured parts.

REFERENCE

1. Q. Wang et al., Sensors, 15, 6, 12857-12871 (2015).

For More Information

Companies mentioned in this article include:

Gentec Electro-Optics

Québec City, QC, Canada

www.gentec-eo.com

Newport

Irvine, CA

www.newport.com

OSI Optoelectronics

Hawthorne, CA

www.osioptoelectronics.com

SiTek Electro-Optics

Partille, Sweden

www.sitek.se

FOR A COMPLETE LISTING OF COMPANIES making position-sensing detectors, visit the Laser Focus World Buyers Guide (www.laserfocusworld.com/directory).

DISCLAIMER: While we try to include information from the broadest possible number of companies that manufacture the products featured in our Photonics Products series, because of limited word count as well as deadlines that cannot always be met by requested contributors, we cannot possibly include all companies and regret if your company is not included in our series.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.