Single-photoelectron calibration of PMTs needs no analytical model

Photomultiplier tubes (PMTs) are essential components of many scientific and other optical systems that are designed to measure very low light levels. For optimal calibration, PMTs are important. Often, a PMT is not being used to count photons singly, but is instead measuring slightly higher levels where the photon signals overlap. However, the PMT must provide an accurate estimate of the photon rate and the relative width of the single photoelectron pulse. In this case, the PMT is conventionally calibrated relative to the mean of the charge distribution that corresponds to the single photoelectron (SPE) produced by a single detected photon. This is done using a very low-intensity light source and an analytical model of the SPE response, but defining that analytical model is extremely difficult because of the complexity of the process.

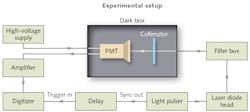

Researchers at the University of Chicago (Chicago, IL) and the Fermi National Accelerator Laboratory (Batavia, IL) have come up with a way to extract the relevant SPE calibration parameters using simple statistics and no assumption about the SPE distribution. To ensure the correct statistical estimate, the approach includes the underamplified component of the SPE response in the estimate of the mean and variance. The researchers experimentally verified the effectiveness of the new method by calibrating a Hamamatsu R11410 PMT, as well as Monte Carlo simulations. Their approach produced accurate estimates of the SPE mean and variance to better than 5% and 6%, respectively, at PMT gain values above 1 × 107. The researchers say that the method is effective over a wide range of intensities, thus allowing calibration of arrays of PMTs that receive nonuniform illumination because of their large size. Reference: R. Saldhana et al., arXiv:1602.03150v1 [physics.ins-det] (Feb. 9, 2016).

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.