Diffractive optics bend, shape, and filter x-ray light

Multilayered diffractive optics that collimate or focus x-ray light and simultaneously render it monochromatic can be economically

mass-produced.

Nicola J. Grupido and Ronald L. Remus

Designers of instruments based on infrared, visible, and ultraviolet light use classical optics such as lenses, filters,and gratings to control light beams. Optical components to monochromatize and either focus or collimate a light beam are readily available, but managing an x-ray beam has proven more difficult.

X-ray instrumentation designers have limited options. Crystals, gratings, or multilayer-coated optics can be used to diffract only the x-ray energy band required for the application. Thin foils or films used in transmission are available to filter lower-energy x-rays. Shaping an x-ray beam requires apertures to block portions of the beam or mirrors that work on the principle of total external reflection. Each of these optical components introduces a significant intensity loss of the desired x-ray energy. Creating a focused or collimated monochromatic beam by combining x-ray optical components results in such low intensity that the instrument is often rendered useless.

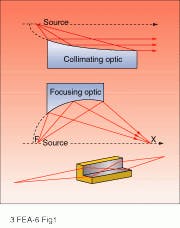

Osmic (Troy, MI), a supplier of multilayer-coated x-ray optical assemblies, has developed diffractive optics for collimating and focusing x-ray beams to address the needs of x-ray instrument designers and users (see photo and Fig. 1). These optics--Max-Flux Optics and Confocal Max-Flux Optics--combine advanced multilayer technology with classical optic design and are currently in use in powder diffraction, protein crystallography, high-resolution diffraction, small-angle scattering, total-reflection x-ray fluorescence spectrometry, and several other x-ray applications. X-ray optics are also under development for select medical applications.

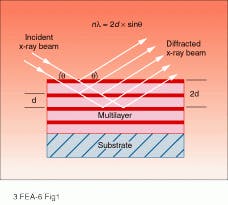

Classical reflective optics designed to collimate or focus light have existed for decades. For a divergent beam of light, reflective collimating optics are parabolic while focusing optics are elliptical in figure. In either design the angle q of a ray of light incident on the surface varies across the length of the optic. For visible light this is not an important consideration. However, it is a critical consideration when one is designing or using x-ray diffractive optics that work for a desired wavelength q according to Bragg`s Law

nl = 2d sinq

where l is the x-ray wavelength, d is the d-spacing of a crystal or multilayer-coated optic, and q is the incident angle.

X-ray diffractive optics such as crystals or soap films with fixed d-spacings cannot be made to function when curved to either parabolic or elliptical optical figures. Historically, the x-ray analog of classical reflective optics has been total-reflection mirrors, not diffractive optics. But x-ray total-reflection mirrors suffer from the physical limitations of a small acceptance angle and a very broad energy bandpass. As a result, achieving a high-intensity monochromatic beam has been practically impossible.

Benefits of multilayer-coated optics

Multilayer-coated x-ray optics, commonly called multilayers, consist of alternating layers of a reflective material and a "spacer" material. They function on the principle of diffraction (see Fig. 2). The alternating regions of high electron density and low electron density simulate the structure of a natural crystal.

X-ray multilayer optics are created using thin-film sputtering, a technique used in production of semiconductor devices, solid-lubricant coatings, wear-resistant coatings, and other advanced coatings. Osmic has worked with PLD Advanced Automation Systems (PLDAAS; Orlando, FL) to design and build a multilayer thin-film sputtering system with capacity to coat many graded multilayer optics. The fully automated "turnkey" high-vacuum production equipment designed, engineered, and fabricated by PLDAAS is used in Osmic`s manufacturing process, which involves coating optics under vacuum with special proprietary reflective materials.

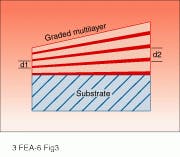

A variant on the uniform multilayer is the laterally graded multilayer coating (see Fig. 3). Because the incident angle of a divergent beam of x-rays onto a parabolic or elliptical surface changes from point to point along the length of the mirror, a uniform multilayer coating would not reflect the same wavelength for the entire mirror. By grading the multilayer`s d-spacing in accord with a precalculated curve along the mirror`s length, the optics can collect a large solid angle from an x-ray source while simultaneously rendering the beam monochromatic. In most applications, the solid angle captured by the optics ranges from 2 to 50 times that of traditional x-ray optics. While the solid angle captured can be several orders of magnitude larger than that of specific x-ray optics, the capture angle remains much lower than that of visible-light optics.

Bending, glueing, and aligning

A graded multilayer is not the only requirement to achieve the design goals of most x-ray applications. Also important in the manufacture of useful optics for a reasonable price is innovative technology for bending, glueing, and aligning high-precision optics. Osmic`s proprietary technology allows multilayer mirrors to be bent and glued to any practical figured surface to create a low-cost optic with very precise optical figure. Even the ends of the mirrors reveal no flattening, a condition that seemed to be unavoidable when using pre-existing technologies.

Applications for multilayer collimating and focusing diffractive optics include biotechnology, thin-film analysis, and micro-focusing for both point-focus lab sources and synchrotrons. In the case of the collimating optics, one could apply these in inverse direction to focus a parallel beam. Both the collimating and focusing optics provide increased intensity over conventional x-ray optics. In the case of the focusing optics, the flux density at the focal point is also significantly increased.

For example, experimental results obtained at the Biomacromolecular Crystallography Facility at Michigan State University (Lansing, MI) indicate a flux gain factor of five times over conventional total-reflection optics used in macromolecule crystallography. This translates into a huge savings in the time required for data collection, which previously could require up to two days. Macromolecular crystallography is the study of the atomic structure of proteins, nucleic acids, and other biological substances. Structural biologists and biomedical researchers employ this x-ray diffraction technique to better understand how viruses, proteins, and pharmaceuticals interact within the human body.

Osmic`s proprietary sputtering system supports the company`s growth in the areas of analytical instrumentation, advanced medical therapeutics and diagnosis, and EUV lithography. The PLDAAS equipment creates coatings with precision on the atomic scale and increases Osmic`s optics coating capability to 1.5 m in length or 40 cm in diameter. Uniform, depth-graded, and laterally graded multilayers will be produced. o

Diffractive optics housed in Osmic`s Confocal Max-Flux x-ray beam focusing instrument achieve three to fives times greater flux at the detector than total-reflection optics in applications such as protein crystallography.

FIGURE 2. Multilayer-coated optics, consisting of bilayers of reflective material alternating with spacer material, operate on the principle of diffraction. The bilayer thickness represents the d-spacing of the Bragg equation (top).

FIGURE 3. Grading bilayer thickness over the length of the substrate enables a monochromatic reflection from a polychromatic divergent source when combined with collimating or focusing optics.

NICOLA J. GRUPIDO is director, sales & marketing, at Osmic Inc., 1788 Northwood Drive, Troy, MI; e-mail: [email protected]. RONALD L. REMUS is CEO and president of PLD Advanced Automation Systems, Research Park, Orlando, FL; e-mail: [email protected].