Application, wavelength, output power, and operating-mode requirements dictate guidelines for choosing appropriate power supplies.

The workhorse behind every semiconductor laser is its power supply, yet choosing the correct power supply is not always given much thought. The choice requires careful planning, because one decision affects the next. Factors that influence power supply selection include the electrical requirements of the laser diode, its physical size, and the price of the power supply.

Laser power supplies can be smaller than a dime or as large as a microwave oven. The two main types of power supply technology are linear and switching. Linear power supplies are used mostly in low-power laser modules. Switching power supplies can be used in pulsed, continuous-wave (CW), and quasi-CW (QCW) systems that typically provide more than 1 A of drive current.

Optical output is crucial

The required optical-output power is the single largest factor that influences the choice of power supply. Because the electricity that the laser consumes is converted to light, there is a direct correlation between the amount of light produced and the amount of electricity required. Different applications can require drastically different amounts of output power, thus input-current requirements can vary widely from one application to another. It is, for example, much easier to find a power supply for a 10-mW visible laser diode than for a 40-W diode array designed for pumping solid-state lasers. The 10-mW laser will require less current and generate less internal heat than the 40-W array, which will need 500 or more times as much current. The power supply must provide adequate current to the laser without overdriving it.

Wavelength requirements have the second largest impact on the choice of a power supply. If there is limited availability of laser diodes for the desired wavelength, the power-supply selection may also be limited. Some wavelengths and power levels can be generated more efficiently than others. A prime example of this is a 6-W-output laser diode at 1870 nm (see photo). At this wavelength, multiple-watt power is difficult to achieve efficiently. A 6-W laser requires 32 A of drive current while a similar 7-W 808-nm laser would draw only about 10 A.

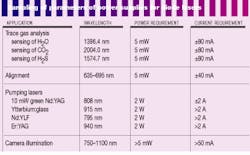

Establishing wavelength parameters can be as simple as determining whether the need is for a visible laser diode for alignment or an infrared light source for a camera. Both applications can use a broad range of wavelengths. The visible laser could operate between 635 and 695 nm. Because most charge-coupled-device (CCD) cameras are silicon-based, an infrared illumination application could be accomplished with lasers in the 750-1100-nm range.

Some high-power applications that may be wavelength dependent include materials processing and solid-state-laser pumping. In cutting applications, for example, some materials have an absorption peak at a particular wavelength. A laser at that wavelength, therefore, cuts the material faster and cleaner. On the other hand, certain laser crystals lase only when pumped at a specific wavelength. The most common example is Nd:YAG, which is most efficiently pumped at 808 nm. Other wavelength-dependent solid-state-pumping applications include Nd:YLF at 795 nm, erbium:YAG at 940 nm, and ytterbium-doped glass at 915 nm. In each of these cases, the required wavelength limits the selection of laser diodes and constrains the choice of power supply (see table).

Operating modes can vary

Laser diode power supplies can operate in one of two modes, constant current (CC) and automatic power control (APC). Most, but certainly not all, smaller laser diodes (5.6- and 9-mm packages) are operated in APC mode. For APC operation, the power supply must have a photodiode mounted inside the laser diode package. The photodiode generates a feedback signal that allows gauging and adjustment of the current supply, keeping the output power of the laser constant over temperature changes and time.

Constant-current power supplies do not contain a photodiode. Instead, they provide a set level of current to the diode. The diode output power will drift when the temperature changes due to the inherent properties of the semiconductor material. Constant-current power supplies generate less electrical noise than APC power supplies, because the APC feedback circuit constantly adjusts the output current. A temperature-controlled thermoelectric cooler can help prevent power and wavelength drift by stabilizing the operating temperature of the laser diode. Higher-power multiple-watt lasers often do not have a photodiode within the diode packaging; they rely on an external photodiode for APC operation or operate in CC mode.

When matching a lower-power laser diode with a power supply, the diode and photodiode configuration must be compatible with the power supply, because diode manufacturers offer a variety of pinout configurations. Users should also confirm that the power supply will operate in the desired mode for the application. Some diode drivers, such as the LDP-201 from Power Technology (Little Rock, AR), are capable of operating in either CC or APC mode, as well as accepting most of the standard pinout configurations.

On-time duration

Another factor to consider when choosing a power supply is the length of time that the diode will be "on." Continuous-wave applications require the laser to be on 100% of the time. In pulsed and modulated operation, the laser is activated only when needed. While CW lasers are best for many applications, pulsed, modulated, or QCW lasers might be better suited. A low-power, 100-mA CW power supply would not be appropriate for a time-of-flight distance-measuring application, for example. Instead, this application would require a specialized pulsed power supply capable of delivering many amps in nanosecond pulses. However, a CW power supply would be required for "constant-on" use, such as in alignment or illumination applications. A QCW power supply may be needed for some high-power laser diode arrays, such as those for materials processing, cutting, and optical pumping.

Modulated laser beam delivery is also an option. There are several laser diode drivers on the market that accept TTL (transistor transistor logic), ECL (emitter-coupled logic) or analog input to modulate the output beam according to an input signal. An example would be the model SPMT laser system from Power Technology, which accepts a 0- to 20-MHp TTL input signal and modulates the diode accordingly. Beam modulation can be used to synchronize a laser with an analytical instrument or camera.

Build or buy?

A company may decide to design and manufacture its own power supplies for applications using laser diodes. While some manufacturers may be able to accomplish this task, most lack the volume to do it cost-effectively. A laser diode power supply is not just a simple voltage-regulated circuit. It is a precision current source designed to protect the laser diode. Power-supply manufacturers also offer a warranty on their products. A wide array of laser diode power supplies are on the market, and the odds are that one will meet a user`s needs. Some manufacturers will custom-design power supplies to meet more-complex requirements.

A laser diode bar emitting 6 W at 1870 nm--a desirable wavelength for solid-state laser pumping and some medical applications but an inefficient power conversion--requires a 32-A current, a more powerful supply than those needed by diodes with easier-to-achieve wavelengths, such as 808 nm.

Walter Burgess | Co-CEO, Power Technology

Walter Burgess is co-CEO at Power Technology (Alexander, AR).