Three-color optical system measures 3D positions of many trapped microparticles

Using three colors of light projected through a microscope objective in different patterns, researchers at the Technical University of Denmark (Roskilde, Denmark) simultaneously and unambiguously find the 3D coordinates of multiple microparticles. The scheme can be used while optically trapping and manipulating the particles, whether by holographic trapping or counterpropagating-beam trapping.

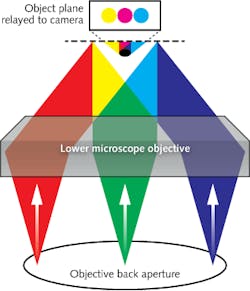

Red, blue, and green (RBG) light patterns are created by an LED-based digital-light-processing (DLP) projector (which actually projects yellow, cyan, and magenta hues that mix to form RBG) and projected into a microscope to the back aperture of the lower objective, with the green projected on-axis. An optically trapped particle casts shadows that are missing one or more of the three colors; from these shadows, the 3D information on the particles is obtained. Because there is some “bleeding” between the colors (for example, both the red and blue illumination patterns produce a detectable signal in the green color plane), the researchers measure the background signal (offset and color-plane bleed ratios) and compensate using a deconvolution algorithm.

In one experiment using a 50X objective with a numerical aperture of 0.55, 6 μm particles were accurately tracked over a 180 μm vertical distance. A video of seven optically trapped microparticles being manipulated while their coordinates are being measured can be seen at http://www.jeos.org/suppfiles/304/304-1729-1-SP.avi. Contact Jesper Glückstad at [email protected].

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.