Self-tracking PV technology concentrates light via fluidic coupling

Glint Photonics (Burlingame, CA) has developed a new optical technology for low-cost solar concentrating photovoltaic (CPV) systems using an embedded liquid layer to passively adjust the optical properties of the concentrator to track the position of the sun. The technology is designed to provide high-concentration panels with a wide effective acceptance angle, eliminating the need for precision mechanical alignment and tracking typically used in CPV systems and thereby making the approach much less expensive. The result is a low-cost flat panel that can be mounted like a conventional silicon module but deliver up to twice the electrical energy.

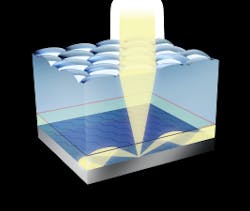

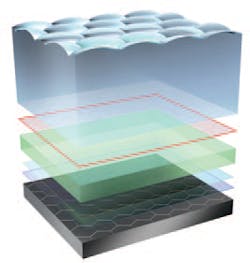

The optical light-collection film is a laminated structure that contains an array of millimeter-scale molded lenslets above a slab light guide. Sunlight is focused by the lenslets to form an array of focal points that move across the bottom face of the slab as the angle of incident light changes. The slab guide is clad on the top by a thin low-index polymer and on the bottom by fluids that provide the passive-tracking functionality. At each focal spot, the fluid cladding provides a local increase in refractive index that allows the focused light to enter the guide after reflecting off the underlying facets. To accomplish this index shift, the fluid cladding is composed of two thin liquid layers: a low-refractive-index fluid on the slab face with a high-refractive-index liquid below it. Local heating at the focal points alters the interface tension between the two fluids via the thermocapillary effect, causing the high-index liquid at each focal point to come into contact with the slab. Because these contact regions are dynamically formed, they follow movement of the focal points as the angle of incident light changes, providing passive solar tracking. Light from all of the lenslets is aggregated into the common guide and can be extracted at the guide edge at concentrations up to 1000X. Contact Peter Kozodoy at[email protected].