Advances in Displays: Quantum dot film lets LCDs express 50% more color

JOHN VAN DERLOFSKE and ART LATHROP

After decades of research and development, the first liquid-crystal displays containing quantum dots (QDs)—molecule-sized spheres of semiconductor materials—are coming to market. These displays will have the ability to express as much as 50% more color than earlier LCDs, resulting in color performance approximately equal to or exceeding that offered by commercialized organic light-emitting diode (OLED) displays.

LCD makers are exploring several technologies for integrating QDs into their manufacturing processes. 3M's Quantum Dot Enhancement Film (3M QDEF) is proving to be an efficient and durable mechanism.

In simple terms, QDs convert color; more precisely, a QD will absorb short wavelengths of light and emit a narrow spectrum of light at longer wavelengths. Because the wavelength of the emitted color is determined by the dot's size, the emission is predictable and tunable. Smaller dots produce shorter wavelengths; larger dots produce longer wavelengths.

For example, when blue photons with a wavelength around 450 nm strike a 3 nm QD, it emits a saturated green light. When those blue photons strike a 7 nm dot, it produces a saturated red light. The degree of control is remarkable; by tailoring the size of the dot, the emitted light can be tuned to within approximately 1 nm of the desired wavelength.

When these green- and red-producing dots combine with the blue light emitted by LEDs, the result is a white light with narrow spectral peaks in the three primary colors.

Why narrow spectral peaks matter

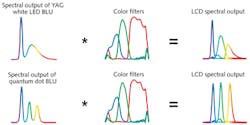

To understand the significance of these narrow primary peaks, consider how light is generated and applied in an LCD. First, the light source in today's conventional LCD backlight unit (BLU) is an array of LEDs. Because these gallium nitride (GaN)-based LEDs typically emit blue light, they are treated with a phosphor—usually of yttrium aluminum garnet (YAG)—so they produce a white light.

Second, this white light shines through a color filter in the LCD panel. This filter is composed of thousands or millions of red, blue, and green subpixels. The light passing through each of these subpixels is controlled to produce each pixel's color.

Typically, the BLU's white light is not centered to the primary red, blue, and green wavelengths. Instead, the white light has significant concentrations of nonprimary wavelengths (such as orange or yellow) that leak through the color filter; as a result, the spectral output is not saturated. In a conventional color filter, for example, a red subpixel will transmit a band of wavelengths greater than 570 nm (a mix of yellow, orange, and red). This mix prevents the LCD from producing a pure red (see Fig. 1).

In contrast, when the BLU combines an untreated (bluish) LED with red and green quantum dots, it generates a white light with most of its energy in the primary red, green, and blue wavelengths. When this light passes through a color filter, the LCD produces concentrated peaks in the primary wavelengths, which can efficiently create a larger gamut with more vivid colors.1

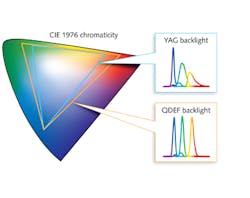

As a result, a QD display can produce a larger color gamut-one that is as much as 50% larger than the gamut produced by a conventional white YAG LED (see Fig. 2).Color gamut overview

The term color gamut is used to describe the palette of colors encompassed by a standard or the range of colors that a given display can represent. Color gamut can also be used to describe the range of colors produced by natural phenomena.

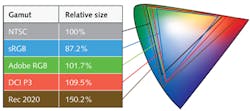

As it relates to image or video encoding, color gamuts typically define red, green, and blue primaries. All other colors are created by mixing these "primary" colors. An example is the National Television System Committee (NTSC) standard established for color televisions in the 1950s. The standard for contemporary HDTVs is Rec. 709; for color monitors, it is the standard red-green-blue (sRGB) gamut (see Fig. 3).Often, the color gamut of a display is described by its relationship to standard color gamuts. The color gamut of most LCD TVs, for example, is around 100% of the Rec 709 standard or 87% of the older NTSC standard (as represented in the CIE 1976 color space; in the older CIE 1931 color space, the gamut of most LCD TVs is approximately 72% of the NTSC standard). Next-generation UHD TVs are expected to achieve the Rec 2020 standard, which is 150% of the NTSC standard. Other devices, such as some tablets and notebooks, can have considerably smaller gamuts.

Manufacturers can now produce larger-color-gamut displays using QDs, OLEDs, or specialized color filters. The color gamuts of these displays are usually described in terms of the Adobe RGB or Digital Cinema Initiatives DCI P3 standards. Adobe RGB is closely associated with printed media, while DCI P3 is more aligned with video creation. Although Adobe RGB offers a slightly wider range of greens, DCI P3 is a larger gamut offering both enhanced reds and greens when compared to the sRGB standard.

Integrating QDs into the LCD

Quantum dots' durability can be affected by exposure to heat, oxygen and water vapor. These sensitivities have helped to shape the strategies for integrating QDs into LCD manufacturing.

In one approach, QDs are encapsulated in a glass tube or "rail," which is positioned directly in front of the LEDs that are ranged along the side of the display. When blue light strikes this rail, some is converted to red and green light and some is transmitted, creating the red, green, and blue primaries. The disadvantage of this architecture is that the dots can be exposed to high heat and flux from the LEDs, which can affect their efficiency and lifetime.2 Rails also add another mechanical element that must be located along the edge of the display, which affects design flexibility and is not practically scalable to smaller display sizes with limited bezel area. Finally, this method requires a reconfiguring of current display manufacturing processes.

A system developed at 3M, called 3M QDEF, provides an alternative mechanism for deploying QDs. This approach reduces exposure to high heat and flux conditions. Integrating the film into current manufacturing processes is relatively straightforward.

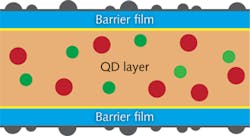

This system is a three-layer stack: an upper barrier film, a middle layer of QDs dispersed in polymer, and a lower barrier film (see Fig. 4). The amount of QDs and the ratio of green to red dots are influenced by the color specifications of the display, the degree of light recycling in the BLU, the properties of the color filters, and the overall thickness of the film.The barrier film represents a significant innovation in terms of flexibility, transparency and permeability.3 It is composed of ultrathin layers with a combined thickness (in the current construction) of just 55 μm. Once laminated, these layers form a barrier to water vapor and oxygen that is several orders of magnitude more impermeable than conventional packaging-grade barrier films.4 The barrier has a water vapor transfer rate of less than 1 × 10-3 g/m2/day at 20°C and provides this protection while being optically clear and flexible. It is also thinner, lighter, more flexible, and more impact-resistant than glass.

Quantum dots are up to 15% more efficient than conventional YAG LEDs and color filters in achieving the sRGB.5 This improvement arises because a display equipped with QDs can express the sRGB gamut using a more transmissive color filter (for example, CF65). Less light is needed from the BLU to achieve the desired display brightness, so less energy is consumed and, in portable devices, battery runtimes are extended.

For larger color gamuts (for example, Adobe RGB or DCI P3), the energy benefit of QDs is even more pronounced. One alternative method for an LCD to express these larger gamuts is through the use of more saturated and less transmissive color filters. Because these filters block more light, the displays require brighter backlight illumination, which requires more power.

Compared to displays using these more saturated color filters, QD displays with typical color filters (for example, CF72) can be up to 50% more energy-efficient in expressing these larger color gamuts.

Accelerated-aging tests indicate that the durability of 3M QDEF exceeds industry requirements. After exposure to standard tests (including thermal cycling and high humidity), 3M QDEF showed a lifetime of 20,000 to 30,000 h, with typical failure from white-point drift. Next-generation 3M QDEF is expected to have greater than a 70,000 h lifetime for most consumer applications.

What's next?

In the near future, we expect a profusion of displays that use QDs. The experience of LCD phones, tablets, and especially televisions will change, becoming more realistic and immersive. During this time, the current mechanisms for employing QDs (rails and 3M QDEF) will be refined. Other methods, such as a coating of dots on the backlight plate, will almost certainly be explored.

Ultimately, QD technology will affect content in new and exciting ways. Videographers, filmmakers, and other content creators will use these expanded color gamuts to more accurately reflect the world around us, to create new effects, and to express emotions and ideas in ways that challenge and stimulate the imagination.

REFERENCES

1. A. Lathrop. "Color as a key differentiator," IHS/SID 2013 Business Conference, Vancouver, BC, Canada (2013).

2. S. Coe-Sullivan, W. Liu, P. Allen, and J. S. Steckel, "Quantum dots for LED downconversion in display applications luminescence and display materials, devices, and processing," ECS J. Solid State Sci. Technol., 2, 2, R3026-R3030 (2013).

3. F. B. McCormick, "Barrier films for displays, lighting, & flexible electronics," Printed Electronics USA, Santa Clara, CA (2013).

4. J. Chen, V, Hardev, and J. Yurek, "Quantum-dot displays: Giving LCDs a competitive edge through color," SID Information Display, 2-7 (2013).

5. J. Van Derlofske and K. Hanley, "Quantum dot enhancement film (QDEF): High color gamut LCDs for improved visual quality," Intel Ecosystem Symposium, Taipei, Taiwan (2013).

John Van Derlofske and Art Lathrop are at the Optical Systems Division of the 3M Company, Maplewood, MN; e-mail: [email protected]; www.3m.com