Spire Corp. (Bedford, MA) is using a four-year, $800,000 contract from the US Army Medical Research Command to develop thin-film cadmium zinc telluride (CdZnTe) detectors for use in digital mammography. According to Spire, the resulting large-area, self-scanned, flat-panel x-ray detector arrays will be more efficient than existing scintillator-based x-ray detector systems and will improve diagnostic capabilities by creating a direct radiography approach for mammography.

For the past several years, there has been a growing trend in diagnostic imaging toward digitization techniques that eliminate the need for film and thereby reduce health-care costs. This work has led to the development of various detectors that can record an image, digitize it, and transmit it directly into a computer in a matter of seconds. Among other things, researchers have found that direct-conversion methods result in higher signal strength than indirect conversion methods, in which light is first generated using a scintillator or phosphor and then detected by charge-coupled devices or thin-film-transistor (TFT) arrays in conjunction with photodiodes.1

Several groups have demonstrated the potential of cadmium telluride (CdTe) detectors for medical-imaging applications such as nuclear medicine (positron emission tomography and single-photon emission computed tomography) and radiology (x-ray computed tomography).2 Two main problems, however, have constrained the commercial potential of CdTe detectors—poor energy resolution, which results primarily from poor charge-collection efficiency—and high cost, because the growth technique produces small polycrystalline crystals. Thus, CdTe detectors have been limited to applications in which miniature detectors would suffice.

More recently, researchers have been investigating CdZnTe devices for diagnostic imaging and other applications in which high energy resolution is critical and large-volume arrays are desired. By alloying CdTe with zinc, resistivity is improved, resulting in lower leakage current in metal-semiconductor-metal detectors. Lower leakage current also allows the use of higher bias voltage, thus improving charge-collection efficiency and permitting the fabrication of larger-volume detectors. These detectors are now available in a wide range of dimensions in commercial quantities.

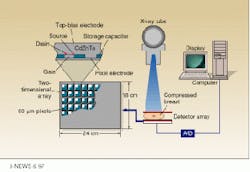

Spire plans to use a continuous photoconductive CdZnTe layer that will make the detector arrays more sensitive to x-rays by acting as a direct converter of x-rays to electrons. For readout, the company will integrate the detectors with large-area (24 × 18 cm), active-matrix cadmium selenide thin-film transistor pixellated arrays (see figure). The approach is similar to previous work done at E. I. du Pont de Nemours (Wilmington, DE), where researchers have developed a digital radiographic system using a multilayer structure consisting of a thin-film pixel array, selenium x-ray photoconductor, dielectric layer, and top electrode.

Spire`s three-phase project will first demonstrate CdZnTe TFTs by fabricating and testing a passive-matrix detector structure deposited on glass or silicon substrates. During phase II, the feasibility of integrating CdZnTe detectors with readout circuitry will be demonstrated by fabricating detectors on a silicon multiplexer. In phase III, Spire researchers will monolithically integrate CdZnTe detectors with CdSe TFTs and perform imaging experiments using phantoms.

Spire is collaborating with researchers from the University of Toronto (Canada) and Massachusetts General Hospital (Boston, MA) on this project, which is being funded by the Army as part of its ongoing efforts to support breast-cancer research and advance digital technologies. Spire is also working with some major medical-device manufacturers on commercial applications of this technology.

REFERENCES

1. D. L. Lee, L. K. Cheung, and L. S. Jeromin, Proc. 1995 SPIE Medical Imaging Conference, 2432 (1995).

2. R. Sudharsanan, K. B. Parnham, and N. H. Karam, Laser Focus World 32 (6), 199 (June 1996).

About the Author

Kathy Kincade

Contributing Editor

Kathy Kincade is the founding editor of BioOptics World and a veteran reporter on optical technologies for biomedicine. She also served as the editor-in-chief of DrBicuspid.com, a web portal for dental professionals.