PHOTONIC FRONTIERS: FREE-ELECTRON LASERS: Hard-x-ray free-electron laser is major milestone for researchers

The Linac Coherent Light Source (LCLS), opening this month at the SLAC National Accelerator Laboratory (Stanford, CA), is the first free-electron laser to emit hard x-rays. Capable of delivering 80 fs pulses containing about 10 trillion x-ray photons at wavelengths tunable between about 0.15 and 1.5 nm, the LCLS offers the potential of advancing science through experiments by guest scientists.1

“This is a landmark event in the history of light-source science, which will open up vast new areas for scientific exploration,” writes Brian McNeil of the University of Strathcylde (Glasgow, Scotland).2

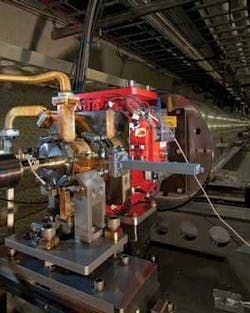

The free-electron laser extracts energy from a beam of energetic electrons passing through a magnetic field that comes from an array of magnets of alternating polarity called undulators. The magnetic field bends the electrons’ paths back and forth, causing them to release energy as light.

Producing hard x-rays requires electrons with very high energy, so LCLS was built to use the final kilometer of the existing two-mile Stanford Linear Accelerator (SLAC). That segment can accelerate electrons to 4.3 to 13.6 billion electron volts (GeV).

User facility instruments

To accommodate a broad community of users, output from LCLS will be switched among several sets of instruments. These include: atomic, molecular, and optical science instruments, including focusing optics, gas delivery system, a high-power laser that can be synchronized with LCLS, and electron, ion, and photon spectrometers; an x-ray correlation spectroscopy instrument; an x-ray pump-probe instrument; a coherent x-ray imaging instrument; soft-x-ray materials-science instruments; and a proposed matter-in-extreme conditions instrument.

“It’s basically an x-ray wavelength strobe” that can take snapshots of extremely short pulses on extremely small scales, says John Galayda, director of LCLS construction. The x-ray pulses should show atoms dissociating from molecules, and be capable of observing chemical reactions and shock waves.

Researchers are excited by prospects for determining the spacing and orientations of atoms in nanoparticles or single biomolecules. Using LCLS to zap single proteins from cell membranes could take years off the time needed to determine their structure by conventional means that require solving difficult problems to grow large enough crystals.

Those are only the obvious examples, says Galayda. “We’re all expecting that the first users will come up with new ideas.”

REFERENCES

- http://lcls.slac.stanford.edu/

- B. McNeil, Nature Photonics 3, p. 375 (July 2009)

- http://hasylab.desy.de/facilities/flash/index_eng.html

Editor’s Note: An expanded, more detailed version of this article can be viewed at www.laserfocusworld.com/articles/367757.

Jeff Hecht | Contributing Editor

Jeff Hecht is a regular contributing editor to Laser Focus World and has been covering the laser industry for 35 years. A prolific book author, Jeff's published works include “Understanding Fiber Optics,” “Understanding Lasers,” “The Laser Guidebook,” and “Beam Weapons: The Next Arms Race.” He also has written books on the histories of lasers and fiber optics, including “City of Light: The Story of Fiber Optics,” and “Beam: The Race to Make the Laser.” Find out more at jeffhecht.com.