Olympus microscope recovers data from damaged optical media

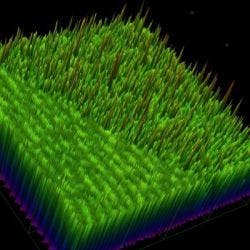

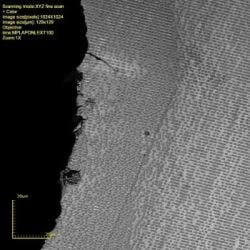

To obtain usable information from damaged optical media (both factory-pressed and home-burned CDs and DVDs), a highly magnified image of the damaged media is created and a region of consecutive dots and dashes is selected. Although the dots and dashes appear to form concentric circles, they actually form a spiral, so there are no beginnings and endings to the apparent tracks (see figure left, scan image; and right, height map). Each dot and dash is then quantitatively measured. Next, the encoding algorithm used to convert the original data into dots and dashes is reversed. (There are only a handful of encoding algorithms in wide use, and most of these are publicly available.) Even if severe data impact has occurred (significant scratches, chemical alterations, surface destruction, or even a disc broken into multiple pieces), it is still possible to adjust the algorithms to recover data based on measurements obtained by the OLS4000. Contact Yuki Kobayashi at [email protected].