FIBER-OPTIC INTERCONNECTS: Electro-optic deflection enables 1 × 35 fiber-optic switch

The same electro-optic (EO) technologies and fabrication capabilities that are used to create Pockel cells and bulk poled frequency-doubling crystals can be combined to create fiber-optic switches and free-space deflectors that can handle higher optical powers than conventional devices. Additional benefits of this combination include higher reliability via the avoidance of any moving parts, and greater compactness enabled by using two-dimensional (2D) deflection. Development of this approach was carried out by AdvR under NASA funding for future space-mission needs.

Currently, beam requirements include polarized single-longitudinal-mode (SLM) light within a 300 to 3000 nm range at up to multiwatt power levels for continuous-wave or pulsed inputs. The wide range of possible device configurations includes amplitude moderators, N × N switches, and deflectors for Q-switching.

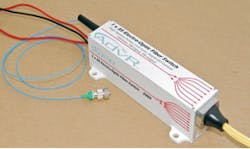

Driven by NASA's specific application, the current focus is on a 1 × 35 switch suitable for handling a multiwatt 1064 nm input beam at a 20 MHz switching speed. Additional specifications include transmission above 70% (a loss of less than 1.5 dB), and crosstalk less than -30 dB.

Fast and flexible routing

A 5 × 7 array of output fibers is used for compactness. The current package at 1.5 × 1.5 × 9 in. in size can be reduced to a length of 4 in. by doubling the path length back on itself (both input and output fibers on the same end of the package). Currently, about 2000 V is required to reach the maximum deflection of the beam in each dimension. By simply setting the appropriate combination of voltages, the beam can be routed to the desired output fiber (see figure).The voltage requirement is primarily a function of the wavelength and degree of deflection. Thus, a range of wavelengths can be handled by the same switch simply by changing to the appropriate voltage settings. However, tradeoffs are required between the wavelength range and the transmission performance due to real-life limitations of coating and lens specifications. To maximize transmission, lensed fibers are used.

Input from customers other than NASA has been key to developing additional device configurations. The many design tradeoffs require a specific application to be assessed in order to define optimal specifications. At current low volumes, the best strategy has been to drive down costs by maximizing the fabrication volume of the standard 1 × 35 switch design. Switches can be cascaded to provide more than 1000 outputs. For applications needing fewer than 35 output fibers, the output capacity can cost-effectively be underused as a result of increased economy of scale; an added advantage in this case is the increased system reliability that results from having spare output fibers.

There are many other types of switch technologies, including EO waveguide, MEMS, and galvanometer. Each technology tends to satisfy particular application requirements, and a strong future is expected for each. Along with the needs of the particular application, the performance characteristics of the required lasers should be considered in the choice of a switch.

Future designs

The initial 1 × 35 embodiment provided to NASA is a solid success, but where will the switch design go from here? The most likely major thrust will be to use the switch in reverse—initially 35 input fibers to one output fiber, and subsequently higher numbers of both input and output fibers.

So far, applications have primarily centered around medical and instrumentation. One unusual use involves switching between the pulses emitted by two lasers of differing wavelengths to create a pulse train with alternating wavelengths for biosensing. Other potential uses include routing one laser source to many locations, and pairing the switch with a free-space output for lidar and other scanning needs.

As for the technology, the main focus is on increasing both switching speed and transmission, while at the same time decreasing the switching voltage. Speed and voltage can both be addressed by using thinner crystals. Initial results indicate a likely increase to speeds of 100 MHz and eventually to 1 GHz. Transmission losses of less than 0.5 dB are expected via improvements to the coupling at both the crystal input and the entrance of the output fibers. A variety of expanded capabilities is possible, including a polarization-insensitive design and a 100-output fiber array.

Tony Roberts | Senior Scientist, AdvR

Tony Roberts is a senior scientist at AdvR (Bozeman, MT).

Bob Tamosaitis | President, AdvR

Bob Tamosaitis is the president at AdvR (Bozeman, MT).