TERAHERTZ DETECTORS: Sensitivity of broadband pyroelectric terahertz detectors continues to improve

DON DOOLEY

Broadband, room-temperature pyroelectric detectors are playing an important role in the research and development of advanced terahertz sources. Interest and funding for these sources have increased dramatically over the past five years as has interest in development of broadband thermal detectors to support the research.

The terahertz portion of the electromagnetic spectrum—between the far-infrared and microwave region or roughly 30–1000 µm or 10 to 0.3 THz—is a special region of interest. Terahertz radiation can penetrate materials such as wood, plastics, and cloth and is absorbed by water or material that contains water—like human tissue. Because it is also nonionizing and therefore not harmful (in lower doses) to humans like x-rays can be, terahertz radiation is attractive for applications such as security scanning of people and baggage, nondestructive testing of airplane wing structures, early detection of cancerous growths, noninvasive testing in microelectronics, and terahertz spectroscopy to identify explosives.

Government agencies have taken the lead in pushing for new developments and improvements in both sources and sensors for terahertz radiation. The US Air Force, the National Science Foundation (Washington, DC), the National Institute of Standards and Technology (NIST; Boulder, CO), and the Defense Advanced Research Projects Agency (DARPA; Arlington, VA), to name a few, have seen fit to fund a number of small business innovation research (SBIR) projects that encourage industry to take part in research and development that will lead to bigger (more intense) sources and better (more sensitive) sensors for these many applications.

Terahertz sources and sensors

Terahertz sources can take a number of forms including thermal, like blackbody sources; electrical such as Gunn diodes and backwave oscillators (BWOs); and optical/laser-based varieties such as quantum cascade lasers (QCLs), CO2-pumped gas lasers, or heterodyne continuous-wave (CW) photo-mixing systems. They can have continuous or pulsed outputs that range from nanowatts to milliwatts and nanojoules to microjoules.

Terahertz sensors also come in many forms: thermal devices like the Golay cell, microbolometer, and pyroelectric detector; and electronic devices like broadband antennas and Schottky diodes. Among all of these devices, recent improvements have been significant in the thermal detector category; specifically, advances in broadband pyroelectric terahertz detectors.

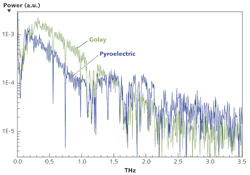

The Golay cell has been the terahertz detector of choice for many years and has long been the measurement standard for terahertz work done by astronomers. These devices respond across the terahertz spectrum with reasonable performance (noise equivalent power, or NEP, of approximately 1.2 × 10-10 W/(Hz)1/2). Even though Golay cells are in use today, some of their deficiencies have forced researchers to look at pyroelectric detectors as an option (see Fig. 1). These deficiencies include the large size of the detector housing and power supply, a limited power range (typically 10 µW maximum), require use with a window, and have slow response time (25 ms) and a relatively high price.

Microbolometers are without question the most sensitive terahertz detectors (NEP of approximately 2 × 10-12 W/(Hz)1/2). They too, have some issues: They must be used at liquid helium temperatures that require an expensive cryostat; they are physically very large (definitely not portable); and they can be very expensive. For the ultimate performance, the microbolometer would be the terahertz detector of choice. But for daily use and basic power or energy measurements, it is just not practical.

Though pyroelectric detectors have also been available for a long time and have some inherent advantages including room-temperature operation, windowless operation, small package, and low price, they have not been a primary choice for terahertz applications. One reason is that the performance of the typical pyroelectric detector hybrid fell short of the Golay cell in terms of NEP or detectivity (D*). In addition, pyroelectric detectors were typically offered as a component, requiring that they be designed into an electronic circuit for use. Fortunately, things have changed in the last few years.

Extending pyroelectric detector performance

Thanks to recent developments in pyroelectric material processing, absorbing coating materials, and advances in electronic circuit noise performance and new digital signal processing (DSP) lock-in software, the performance of pyroelectric detectors has improved and now matches or exceeds that of the Golay cell.

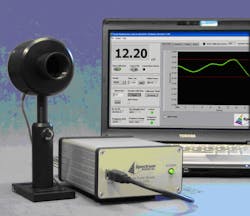

New broadband digital radiometers are available with easy-to-use LabView software that measure at the 50 nW level with 2 nW resolution in the 30 THz to 3 THz region.

Pyroelectric detectors are alternating-current (AC) current sources whose current output varies inversely with the thickness of the material and rate of change of temperature. A simplified equation for current responsivity (Ri) is Ri = p(T)ά/ρcpd, where p(T) = pyroelectric coefficient, ά = coating absorption coefficient, ρ = density of the crystal, cp = specific heat, and d = crystal thickness. From the equation, it can be seen that reducing the crystal thickness and increasing the coating absorption will increase the current output and therefore improve the optical performance of a pyroelectric detector.

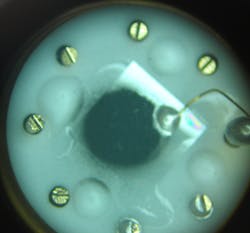

New material-processing techniques such as ion milling and ion slicing have made available lithium tantalate oxide (LiTaO3) and lithium niobate oxide (LiNO3) materials with thickness of less than 10 µm. And it appears that thin-film materials a few microns thick might be possible in the not-so-distant future. In years past, 25 µm thickness was achieved with standard optical grinding and polishing techniques and was the practical limit for LiTaO3 materials. Detectors made from 25 µm materials exhibit a current responsivity of around 1 µA/W. Using the new thin-film materials, we have seen current responsivity values higher than 4 µA/W, resulting in hybrid detector optical amplifier performance of <1.0 × 10-10 W/(Hz)1/2.

The challenges do not stop with producing these thin films; new methods of handling and transferring these films to a carrier substrate are needed to protect them during subsequent processing. As these methods improve, we expect to manufacture large-area detectors (5 mm diameter) that will result in 10X improvements in detectivity specifications. Size is important in the terahertz arena because of the limited ability to focus long-wavelength radiation to a small area. Already, these thin-film LiTaO3 pyroelectric detectors are commercially available (see Fig. 2).There is still a lot to learn

Although the performance of broadband pyroelectric terahertz detectors and instruments continues to improve, there is still a lot to learn and many more improvements to come. Spectral characterization and calibration in the 0.3 to 10 THz region remains the single most difficult task to accomplish today. Unfortunately, a program to tackle this challenge is not yet in place at NIST in the United States. However, there are many willing partners at numerous universities around the world who would like to help with this dilemma; several standards laboratories in other countries such as the National Physical Laboratory (NPL) in England and the Physikalisch-Technische Bundesanstalt (PTB)—the National Metrology Institute of Germany—are working toward this capability now. As the market for terahertz sources, sensors, and systems grows over the next decade, expect to see continuous improvements in the form, fit, function, and calibration of broadband pyroelectric detectors for the terahertz field.

Don Dooley is president of Spectrum Detector, 5825 Jean Road, Lake Oswego, OR 97035; e-mail: [email protected]; www.spectrumdetector.com.