NEXT-GENERATION FIBERS: Chalcogenide photonic-crystal fibers expand nonlinear applications

DAVID MÉCHIN, LAURENT BRILLAND, JOHANN TROLES, QUENTIN COULOMBIER, DUC MINH NGUYEN, MONIQUE THUAL, and THIERRY CHARTIER

Chalcogenide glasses are based on a mixture of chalcogen elements (sulphur, selenium, and tellurium) and other elements such as arsenic, germanium, antimony, or gallium. Compared to silica glasses, they offer several distinctive optical properties such as a transmission window that extends far into the infrared (IR) spectral region (up to 25 µm for telluride glasses). Chalcogenide glasses also exhibit an extremely high nonlinear refractive-index coefficient that can be two or three orders of magnitude greater than that of silica at 1.55 µm. These nonlinear properties can be further enhanced by drawing chalcogenide glasses into photonic crystal fibers (PCFs) due to the possibility of designing such fibers with a very small core diameter.1, 2 These newly developed fibers enable nonlinear active optical functions such as supercontinuum generation in the mid-IR and optical gates.3

Photonic crystal fibers also exhibit several other interesting properties including endlessly single-mode operation, widely tunable chromatic dispersion, and single-mode guiding with a large effective area that can be extended into the mid-IR by using chalcogenide PCFs (CPCFs). In terms of passive optical functions, CPCFs should be useful for power delivery, nulling interferometry for space-based applications, and pollutant detection using optical sensors.

Since 2004, Perfos and the laboratory "Glass and Ceramics" of Rennes University (EVC) have worked together to develop a reliable fabrication method for CPCFs.4 Initially, the common "stack and draw" technique was explored. This method has been widely used for more than a decade to make silica PCF and involves stacking glass capillaries in a hexagonal lattice of several rings, surrounding them with a glass jacket to form the fiber preform. However, this method is not well suited for chalcogenide glasses as we have observed the presence of a great number of bubbles and an induced refractive-index variation at the glass interface region that causes significant scattering losses (>15 dB/m).5 The reduction of optical losses for these fibers remains a challenge and prompted Perfos and EVC to investigate a new fabrication technique for chalcogenide preforms based on the glass-casting process.6

A new preform fabrication method

In the casting method, rods made of highly purified glass are first created with a sealed silica tube method. The different elements are poured into a silica ampoule and placed under vacuum for several hours. The glass is then synthesized at a temperature close to 800°C for 12 hours in a rocking furnace. It is then quenched under water and annealed around the glass transition temperature Tg (several hundreds of degrees Celsius). Other specific thermal treatments such as distillations are necessary to remove impurities such as carbon and water.

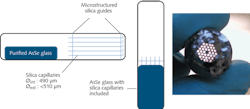

The mold, which is entirely made of silica, contains silica capillaries threaded into silica hexagonal guides in a silica ampoule. A glass rod is first placed at the top of the mold and is then heated to become almost liquid. It must be soft enough to flow in the silica mold. Once the glass is in the mold, the tube is then quenched in air and annealed at Tg. The silica capillaries are removed by applying a hydrofluoric acid solution (see Fig. 1).

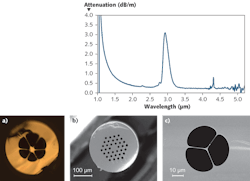

The key point of the process is the thickness of the silica capillaries. If they are too thick, they induce glass breaking because the thermal expansion of silica is two orders of magnitude lower than in chalcogenide glasses. However, if the capillary thickness is smaller than 20 µm, the capillaries are flexible enough to prevent glass breaking. The casting method allows various CPCF designs with different types of suspended-core fibers and a more common design with a cladding made of several rings of holes (see Fig. 2). This process significantly improves the optical transmission of CPCFs.We measured the attenuation of a multimode six-hole arsenic-selenide (AsSe) suspended-core fiber (core diameter, dcore = 16 µm) using a Fourier transform IR (FTIR) analyzer and an indium-antimonide (InSb) detector and found it to be 0.75 dB/m at 1.55 µm and 0.3 dB/m beyond 3.5 µm. These attenuation values are very close to the material losses. This fiber design is particularly suitable for sensing applications based on detecting the absorption of various chemical species in the IR region such as carbon dioxide (CO2) at 4.3 µm or methane (CH4) around 3 µm, for example. Recently, CPCFs have been successfully implemented in fiber evanescent-wave spectroscopy systems to detect CO2 gas.7

Another fiber design with several rings of holes has been developed wherein the size of the holes and their arrangement in the cladding enable an endlessly single-mode propagation regime. The glass composition chosen was tellurium arsenic selenide (TeAsSe), which exhibits good optical transmission in the spectral range from 2 to 11 µm. The output profiles of the guided mode at 3.39 µm and 9.3 µm were investigated using a near-field measurement confirming the single-mode operation of the fiber. Such designs could help to filter mid-IR signals in nulling interferometers used for space applications.

A third design is a three-hole suspended core AsSe preform that enables the fabrication of an optical fiber with a very small core (diameter = 3 µm, loss = 0.9 dB/m at 1.55 µm) for nonlinear applications. In particular, this design has attracted interest for supercontinuum generation in the mid-IR region. The zero-dispersion wavelength (ZDW) of chalcogenide glasses is beyond 4 µm, but it can be tailored below 2 µm using a suspended-core design.

Record-high nonlinearities

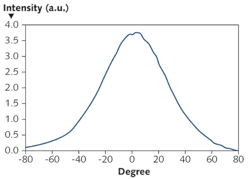

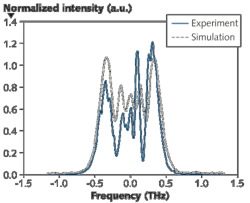

FOTON tested a three-hole suspended-core fiber for nonlinear applications around 1.55 µm.8 The effective area of the fiber was measured using a far-field method; output intensity was recorded with a photodiode moving in a circular path at a fixed distance from the fiber output for different rotation angles (see Fig. 3). To calculate the effective area, the far-field data was converted to the near field using the inverse Hankel transform. With this method, an effective area Aeff of 1.7 ±0.1 µm2 was calculated; this is one of the smallest values demonstrated to date for a chalcogenide fiber.To the best of our knowledge, the single-mode AsSe CPCF fabricated by the casting glass process developed by Perfos and the Laboratory for Glass and Ceramics of Rennes University has the highest nonlinear coefficient value reported for a nontapered optical fiber. Spectral broadening generated by SPM also led to demonstration of an efficient nonlinear optical gate at 1.55 µm by FOTON. These fabrication advances should open the gates to a wide range of new CPCF applications.

Acknowledgments

The authors would like to thank Thanh Nam Nguyen from PTIT (Hanoi, Vietnam), Sy Dat Le from FOTON, and Achille Monteville from Perfos for their contributions. This work was supported by the Agence Nationale de la Recherche and the Université Européenne de Bretagne.

REFERENCES

- L. Brilland et al., Opt. Exp. 14, 3, p. 1280–1285 (2006).

- T.M. Monro et al., Electron. Lett. 36, 24, pp. 1998–2000 (Nov. 23, 2000).

- J. Fatome et al., J. Lightwave Technol. 27, 11, pp. 1707–1715 (June 1, 2009).

- J. Troles et al., Fiber and Integrated Opt. 28, 1, pp. 11–26 (2009).

- L. Brilland et al., J. Ceramic Soc. of Japan 116, 10, pp. 1024–1027 (2008).

- Q. Coulombier et al., Opt. Exp. 18, 8 (2010).

- F. Charpentier et al., Sensor Lett. 7, 5, pp. 745–749 (2009).

- T.N. Nguyen et al., ECOC 2009 paper presentation (Sept. 24, 2009).

David Méchin is program director and Laurent Brilland is a research scientist at Perfos, 11 rue de Broglie, 22300 Lannion, France; e-mail: [email protected]; www.perfos.com. Johann Troles is associate professor and Quentin Coulombier is a PhD student at Equipe Verres et Céramiques, Université Européenne de Bretagne, Rennes, France; www.verceram.univ-rennes1.fr/. Duc Minh Nguyen is a PhD student, Monique Thual is professor, and Thierry Chartier is associate professor at Laboratoire FOTON, Université Européenne de Bretagne, Lannion, France; www.foton.enssat.fr.