Pen with VCSEL replaces computer mouse

Repetitive strain injuries linked to the use of personal computers (PCs) are attributed to the awkward positions both the keyboard and mouse force the hand into. Revamping the two types of input devices has been tried time and again, with varying results. In the case of the mouse, a workable alternative is the pen-shaped input device. One version developed by engineers at Kanitech International (Kolding, Denmark) designs the pen around a vertical-cavity surface-emitting laser (VCSEL).

The group wanted to develop a low-cost—yet precise—system that could probe the rotation in two directions of a 4-mm-diameter ball placed in the tip of the pen. Several possibilities were considered, including marking of the ball and magnetic recording and readout. These avenues all suffered from shortcomings such as a lack of precision, high cost, or excessive power consumption. The last was an especially important issue, as a pen-shaped input device should be cordless and have a power consumption of less than 80 mW when operating.

Researchers at Risø National Laboratory (Roskilde, Denmark) have been working with dedicated laser-based systems for probing torsional vibrations, intending to use them for process monitoring of rotating machinery. These systems rely on laser diodes that are large and costly and consume too much power. Experiments showed that VCSELs are able to create speckles with a very high contrast; this combined with the affordable price and the low angle of divergence for the output beam make them advantageous for this application—and for pen-based input devices as well.

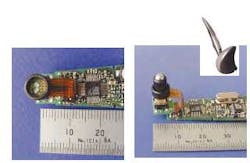

The pen developed by Kanitech—now commercially introduced—contains an optical system and a printed-circuit board with two application-specific integrated circuits (ASICs) that perform the necessary signal processing and transmission to the PC via the penholder (see figure). With a diameter of 5 mm, the optical unit contains a 300 × 300-µm VCSEL without external collimating optics, as well as two sets of orthogonally placed double detectors 60 µm × 1.5 mm in size. The semireflecting steel ball is located a distance of 7 mm from the optical unit.

As the ball rotates, a speckle pattern moves across the two detector pairs, each of which captures the movement perpendicular to its main axis. The number of speckles crossing a detector reflects one component of the displacement of the pen tip, and the sequence in which the speckles traverse the two adjacent detectors in a pair reveals the direction of motion.

The electronic processing is performed by a dedicated ASIC; the x and y counts with directional information are transferred to a transmitter ASIC that sends the information along at an update rate of 40 Hz. To fully benefit from the freedom of using a pen, a pattern-recognition system in the device driver can identify PC commands drawn with the pen.

The technology may find use elsewhere also, according to Steen Hanson, head of the research program on optical diagnostics and information processing at Risø National Laboratory. "An urgent need for noncontact displacement sensors in industry may be fulfilled by combining VCSELs with miniaturized optical components, either refractive or diffractive type. In addition, low-cost detector arrays with on-board processors may join in and expand the possibilities even further," he says.