BY KARL R. BLASIUS, STEPHEN J. FERRY, STEVEN H. SILVERMAN, DANIEL F. MURPHY, PHILIP R. CHRISTENSEN, AND GREG L. MEHALL

The Thermal Emission Imaging System (THEMIS) is a compact multispectral imager built by Raytheon Santa Barbara Remote Sensing for Arizona State University to fly on NASA's Mars 2001 Odyssey orbiter, which was launched in April of 2001. The THEMIS instrument is now in Mars orbit, with the principal missions of mapping surface mineralogy and searching for current hydrothermal activity.

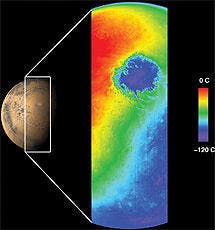

A long-wave infrared image acquired by THEMIS Oct. 30, 2001, from the Odyssey spacecraft 22,000 km above Mars shows surface features as small as 5.5 km. The blue circular feature is the south polar carbon dioxide ice cap in late spring at a surface temperature of -120°C (-184°F).

The revolutionary design of THEMIS allows collection of images in both the long-wave infrared (LWIR) and visible sections of the spectrum. Spectral sampling includes nine LWIR bands in the wavelength range of 6.5 to 15.5 μm at a spatial resolution of 100 m per pixel, plus five bands of visible imaging at 18 m per pixel.1 Light-weight precision optics and uncooled commercial detector technology address the scientific requirements of the Odyssey mission within a limited planetary exploration budget.2

Focal plane assemblies

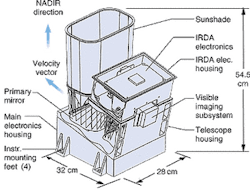

The visible and infrared (IR) imaging on THEMIS occurs on two focal planes. The system optimizes the high signal performance required for the LWIR and the spatial resolution needed for the visible. Notably absent from the design of THEMIS is a cryocooler for the IR detectors, resulting in significant savings in mass and power. The THEMIS system weighs 13 kg and runs on 12 W of power (see Fig. 1).

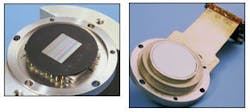

The IR detector assembly (IRDA) incorporates an array of microbolometer detectors, a key design element built by Raytheon Infrared Operations (Goleta, CA).3 These uncooled vanadium oxide detectors, produced under license from Honeywell (Morristown, NJ), allow low-cost LWIR multispectral imaging. The IRDA design is similar to that of components in military and industrial cameras. The array measures 320 detectors cross-track by 240 along-track with a square 50-μm pitch. The microbolometers are grown directly on the surface of the silicon readout integrated circuit.

Nine narrowband stripe filters mounted above the detector array provide spectral discrimination. Each filter covers 16 usable detector rows (see Fig. 2). The array and filters are mounted within a sealed dewar that allows for simplified ambient testing. The forward orbital velocity of the "push broom" imager sweeps the ground image across the two-dimensional detector arrays. Images are recorded in the time interval it takes for a ground feature to traverse a single detector field-of-view (FOV). Detector responses in adjacent rows under a common filter are combined by the use of time delay and integration (TDI) to improve the instrument's noise-equivalent delta temperature (NEDT). The dwell time for a single-pixel ground-sample distance (GSD) of 100 m is 33 ms.

The visible imaging subsystem (VIS) provides a second focal plane with CCD detectors to acquire 18-m-resolution visible images for the study of small-scale surface morphology. The focal plane assembly consists of five narrowband filter strips mounted over a Kodak KAI-1001 CCD array of 1024 x 1024 9-μm detectors. Each strip covers one-fifth of the array. The five spectral bands are centered near 425, 550, 650, 750, and 860 nm. Malin Space Science Systems (San Diego, CA) provided the VIS for integration into THEMIS, behind a shared reflective telescope and beamsplitter.

Optical design

To integrate the visible and IR multispectral imaging capabilities into a single compact instrument, THEMIS incorporates a fast, wide FOV reflective telescope and beamsplitter. The 3.5° x 4.6° FOV is achieved with a three-mirror f/1.6 reflective triplet with an effective aperture of 12 cm and focal length of 20 cm.

A key contributor to the low mass and high performance of the system is the use of diamond-turned bolt-together telescope technology. Designers adopted this approach to simplify fabrication, alignment, and testing. Design and analysis techniques allowed modeling of complex off-axis designs.

High-precision machining capabilities allowed the entire optical stage to be machined and assembled without manual optical-component adjustments, and achieved diffraction-limited performance in both the visible and IR. The tolerances of the specified mounting surfaces are extremely tight (±0.0002 in.). The optical surfaces are machined directly from high-order aspheric equations. The telescope, manufactured by Axsys Technologies (Rocky Hill, CT), is constructed of aluminum and is significantly lightweight. Nickel plating and automated post-polishing keep the surface scatter to levels unobtainable with conventional diamond-turning techniques.

Successful science

THEMIS successfully demonstrated its imaging capabilities shortly after Mars orbital insertion, when Odyssey was high above the South Pole (see figure, p. 47). A wide range of surface temperatures was found to be consistent with models and observations by a precursor IR sensor, the Thermal Emission Spectrometer (TES) on Mars Global Surveyor.4 THEMIS began systematic high-resolution (100-m GSD) imaging in February from a lower altitude with an image ground-sample distance (GSD) of 100 m.

The THEMIS observations will extend the global IR temperature and emissivity database for Mars to finer spatial resolution than that measured by TES, 100-m vs. 5-km GSD. The THEMIS instrument samples a smaller set of spectral bands (9 vs. 143), which are chosen to optimize discrimination of surface minerals. The thermal-IR region of the spectrum contains the fundamental vibrational absorption bands that provide diagnostic information on mineral composition.5 Scientists will also search LWIR images collected at night for warm-temperature anomalies suggesting volcanism or hot springs.

Remote sensing studies of natural surfaces and laboratory measurements have demonstrated that eight to ten spectral bands in LWIR can detect minerals at abundances of 10%. The THEMIS imager supports this level of mineral discrimination by achieving low noise-equivalent delta temperature uncertainties (NEDT). For example, at 10 μm, the NEDT is expected to be less than 0.5 K for a daytime scene at 245 K. Observations in LWIR are specifically advantageous over shorter wavelengths because of large penetration distances through atmospheric dust and surface coatings, and the absorption strengths for fundamental vibrations are linearly proportional to mineral abundance.

As the Odyssey mission proceeds in 2002 and 2003, THEMIS will map Mars in 14 spectral bands at spatial resolutions comparable to Landsat images of Earth.6 This global knowledge base of mineral distribution, temperature signatures, and surface morphology will provide a foundation for future lander and sample return missions.

ACKNOWLEDGMENTS

The authors wish to thank the many contributors to the THEMIS instrument, including the hardware testing and integration team at Raytheon Santa Barbara Remote Sensing, the IRDA team at Raytheon Infrared Operations, the VIS team at Malin Space Science Systems, the software development team at Arizona State University, and investigation management at the Jet Propulsion Laboratory.

REFERENCES

1. S. H. Silverman et al., Proc. 1999 IEEE Aerospace Conf.

2. P. R. Christensen, Reviews of Geophysics, American Geophysical Union, in press (2002).

3. D. F. Murphy et al., Proc. 2000 IEEE Aerospace Conf.

4. P. R. Christensen et al., J. Geophys. Res. 97, 7719 (1992).

5. P. R. Christensen et al., J. Geophys. Res. 105, 9735 (2000).

6. See http://mars.jpl.nasa.gov/odyssey/ and http://themis.asu.edu/.

KARL R. BLASIUS, STEPHEN J. FERRY, and STEVEN H. SILVERMAN are project engineers at Raytheon Santa Barbara Remote Sensing, Goleta, CA; e-mail: [email protected]. DANIEL F. MURPHY is an engineer at Raytheon Infrared Operations, Goleta, CA; and PHILIP R. CHRISTENSEN and GREG L. MEHALL are scientists with the Dept. of Geological Sciences, Arizona State University, Tempe, AZ.