QUANTUM-DOT DETECTORS: Quantum-dot IR photodetectors get ‘hotter’

MANIJEH RAZEGHI

Most current infrared focal-plane arrays (FPAs) are based on quantum-well infrared (IR) photodetectors (QWIPs) or mercury cadmium telluride (MCT) intrinsic photodetectors, and both types of detectors suffer from significant disadvantages.

Quantum-well IR photodetectors do not absorb much light at normal incidence because the optical transition for light striking normal to the surface is forbidden. Gratings can be used to get around this problem, but the additional fabrication steps increase cost. Furthermore, QWIPs are unsuitable for high-temperature operation because of their high dark current. So they are usually operated at low temperature and require cooling, which adds significant cost, bulk, and power consumption to the imaging system.

In the case of MCT-based detectors, instability of the MCT makes it difficult to achieve high-uniformity detector arrays—so focal-plane arrays based on MCT suffer from high cost and poor yield.

Recent improvements to the operating temperature and quantum efficiency of quantum-dot infrared photodetectors (QDIPs) may lead to new imaging techniques that can be applied to medical and biological imaging, environmental and chemical monitoring, night vision, and infrared imaging from space. By using nanotechnology to form quantum dots, our research group is a step closer to developing high-performance imagers that can operate at or close to room temperatures.

Quantum dots, also known as “artificial atoms,” have been widely investigated as a means of improving a variety of electronic and optoelectronic devices. Their small size, usually around 10 nm, gives quantum dots a unique physical property of three-dimensional confinement that can enable higher operating temperatures when used in IR detectors.

Development of an IR photon detector that can operate at higher temperatures will enable the use of cheaper, lighter, and more efficient cooling methods when designing IR imaging systems. This will allow much broader application of IR detectors. Our group had previously fabricated and tested the world’s first QDIP focal-plane array.

QDIP operates at room temperature

More recently, we made a significant breakthrough in the development of high-performance QDIPs. We developed a QDIP that operates at room temperature with a peak detection wavelength in the technologically important mid-IR wavelength range—wavelengths between 3 and 5 µm are important because they are not susceptible to absorption by Earth’s atmosphere.

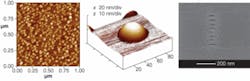

The QDIP device consists of 25 stacks of a hybrid structure of indium arsenide (InAs) quantum dots and an indium gallium arsenide (InGaAs) quantum well, with aluminum indium arsenide (AlInAs) as a barrier. The whole device structure was grown on an indium phosphide (InP) substrate by low-pressure metal-organic chemical-vapor deposition (MOCVD). The InAs quantum dots were grown by self-assembly of the Stranski-Krastanow growth mode. The structural properties of the quantum dots, such as size and density, were characterized by tools including an atomic-force microscope and a scanning-electron microscope (see Fig. 1).

We measured the spectral response of the detector at several temperatures and applied biases in the normal incidence configuration without any optical coupling structures. Spectral response with a peak detection wavelength at 4.1 µm was measured up to room temperature. The responsivity increased with temperature from 77 K to 200 K and started decreasing above 200 K. The peak responsivity was measured to be 822 mA/W at 150 K and -5 V. The specific detectivity was measured to be 2.8 × 1011 cmHz1/2/W at 120 K, 4 × 1010 cmHz1/2/W at 150 K, and 6 × 107 cmHz1/2/W at room temperature. The quantum efficiency at 150 K was 35%. This record performance was published in March of 2007.1 Devices developed since then have exhibited further improved performance—with a quantum efficiency of 48%—through the optimization of the quantum-dot growth, which led to stronger IR absorption.

We have used this technology to build a 320 × 256 FPA with 30 µm pitch and 25 × 25 µm2 pixel size. We demonstrated thermal imaging at temperatures up to 200 K, which is the highest operational temperature ever demonstrated for a QDIP focal-plane array. The array had a peak detection wavelength of 4 µm, aresponsivity of 34 mA/W, a conversion efficiency of 1.1%, and anoise equivalent temperature difference (NEDT) of 344 mK at an operating temperatureof 120 K (see Fig. 2).2

AUTHORS NOTE

The work on the InP-based QDIP and FPA was presented at the 25th Annual Army Research Conference in November 2006 and won a Best Paper Award at the conference.

REFERENCES

1. H. Lim, S. Tsao, W. Zhang, and M. Razeghi, Appl. Phys. Lett. 90, 131112, (2007).

2. S. Tsao, H. Lim, W. Zhang, and M. Razeghi, Appl. Phys. Lett. 90, 201109, (2007).

Manijeh Razeghi is the Walter P. Murphy Professor and director of the Center for Quantum Devices, Department of Electrical Engineering and Computer Science at Northwestern University, 2220 Campus Drive, Evanston, IL 60208; e-mail [email protected]; cqd.eecs.northwestern.edu.