Hyperspectral imager captures whole spectrum without scanning

In a novel hyperspectral device developed by researchers at the Italian National Research Institute for Metrology (INRiM; Turin, Italy), each pixel of the resulting 2‑D image contains the full spectral composition of the object. Unlike other hyperspectral devices having similar characteristics, this device does not use mechanical scanning systems, making it more compact and lower in cost. It is based on a thin Fabry-Perot cavity placed between the lens and the sensor of a digital-imaging system. An interferogram is formed on each pixel when scanning the cavity length; software then estimates the spectrum from the interferogram.

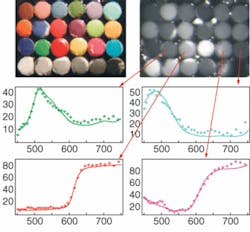

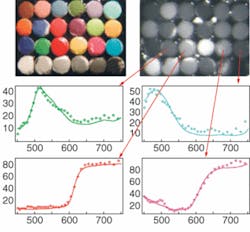

The prototype has a spectral resolution of a few nanometers and a spatial resolution of 640 × 480 pixels. Its compactness allows it to be easily integrated in existing optical systems. Typical applications are industrial process control, chemical analysis, radiation thermal analysis, biology, satellite Earth surveys (environment and security), astronomy, fluorescence microscopy, radiometry, colorimetry, and paintings and other cultural objects. In one example, a colorimetric standard (top left) is captured with the image spectrometer. Each pixel of the hyperspectral image (top right) contains the spectral composition of the impinging light. Some measured spectra (diamonds) are plotted with reference spectra (solid lines). Contact Massimo E. Zucco at [email protected] or Marco Pisani at [email protected]. (Photo courtesy of INRiM)