TERAHERTZ IMAGING: Fiber-pumped terahertz system spots concealed objects in real time

As has been known for years, optical imaging systems based on terahertz radiation—which can pass through clothing and other shielding materials—have great potential for security-related applications such as screening at airports. One hindrance to their wider use is the low average output power of most compact terahertz emitters. In their quest to make terahertz systems more practical, engineers at BAE Systems (Nashua, NH) have developed a nonlinear-crystal-based, fiber-laser-pumped terahertz source that produces tunable narrowband radiation with high average power over the 0.8-to-2.45 THz spectral region.1

Radio frequency (RF) and IR means of generating terahertz radiation were both pursued at BAE Systems, says engineer Daniel Creeden. “However, RF-based technologies seem to severely decrease in efficiency at higher frequencies (above 500 GHz),” he notes. In addition, Creeden and his colleagues had much optical technology at BAE Systems to draw upon, including electro-optics experience, high-power ytterbium (Yb)-doped fiber-laser systems, and an in-house nonlinear-materials group that has fabrication capabilities.

The source they developed is based on an all-fiber master-oscillator fiber amplifier (MOFA) and a zinc germanium phosphide (ZGP) nonlinear crystal. Two semiconductor seed diodes, one fixed at 1064.2 nm and the other centered at 1059 nm but tunable, are preamplified in separate single-mode stages; their light is polarization-combined and amplified in a series of Yb-doped fiber amplifiers. At the fiber output, the light is collimated and focused onto the ZGP crystal. The resulting terahertz radiation is collimated by a parabolic mirror, filtered, and focused by a second mirror onto a sensor array. The image sensor, an uncooled vanadium oxide microbolometer array, is also in-house technology, manufactured at BAE Systems’ Lexington, MA, location.

The average output power of the source reached 2 mW at 2.45 THz. The whole setup easily fits into a laptop-computer-size volume and could be packaged into a handheld unit if necessary, says Peter Ketteridge, senior principal physicist at BAE Systems.

Real-time imaging

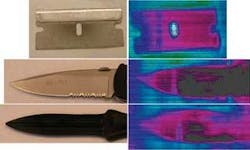

In a video-rate transmission imaging test, the terahertz system was able to image a razor blade, a pocket knife, and a fiberglass knife (which is invisible to metal detectors) in high-performance Tyvek envelopes passed through the terahertz beam (see figure). “Currently, our goal is to demonstrate imaging of concealed objects on a moving person (using a reflection-based imaging scheme) at a stand-off distance of greater than 10 m,” says Creeden. The group is looking at growing engineered (orientation-patterned) nonlinear materials as a replacement for the uniform ZGP crystal.

“We foresee future applications of terahertz in the area of security and homeland defense, although others have shown that terahertz could be used to inspect for defects on an assembly line,” notes Creeden. “Primarily, we are looking at identifying concealed objects and possible threats (chemical, biological, nuclear) in concealed locations, especially in airport security, border security, postal screening, and port security over stand-off distances. Another enabler of this technology is that different materials have different properties in the terahertz region, allowing for the detection of various chemical or biological agents. With a sensitive-enough detector, terahertz technologies may also provide a compact solution to IED (improvised explosive device) detection.”

REFERENCE

1. D. Creeden et al., Advanced Solid-State Photonics 2007, Jan. 28-31, 2007; postdeadline session MF, paper 7.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.