X-RAY IMAGING: Single-shot x-ray diffraction aims at imaging macromolecules

The desire to image macro- and biomolecules is driving the move to very short wavelengths. X-rays have long been used to examine periodic structures such as atoms in crystals; while this use requires only fairly weak x-ray radiation to generate a unique diffraction pattern, imaging a single molecule at x-ray wavelengths will require a much more intense, spatially confined beam for illumination.

Fortunately, sources for intense coherent x-ray beams are being developed; however, radiation damage significantly limits the capabilities of conventional approaches. Damage is caused by energy deposited into the sample by the probes used for imaging (this applies to other types of high-resolution probe beams as well, such as electron or neutron beams). Cooling can slow down sample deterioration, but it cannot eliminate damage-induced sample movement during conventional measurements. The molecule can lose its binding electrons and break before giving rise to its specific diffraction pattern.

A few years ago, researchers at Uppsala University (Uppsala, Sweden) predicted that ultrashort, high-intensity x-ray pulses from free-electron lasers could allow diffractive imaging of single biological molecules.1 The idea was to take advantage of the mass inertia of atomic constituents against kinetic disintegration during the build-up of Coulomb potential by ionization. Those authors calculated the radiation damage as a function of photon energy, pulse length, and intensity and found that, during interaction with a single x-ray pulse, a molecule generates its specific diffraction pattern a few femtoseconds before being significantly damaged.

X-ray free-electron laser

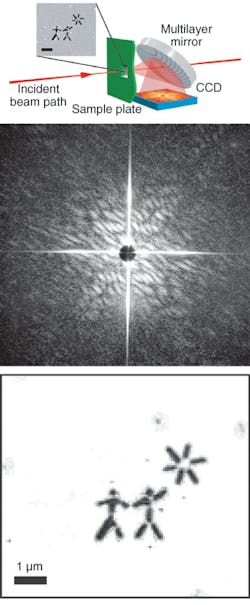

Now an international working group based at Deutsches Elektronen-Synchrotron (DESY; Hamburg, Germany), which includes the Uppsala team and a team from Lawrence Livermore National Laboratory (Livermore, CA), has investigated that prediction experimentally, using DESY’s recently completed soft-x-ray gigawatt free-electron laser.2, 3 As a first test at a 32 nm wavelength, a single micrometer-size pattern cut through a 20 nm silicon nitride membrane was used as the scattering object (rather than a molecule, which is the ultimate goal), just to show that a diffraction pattern can be obtained from such a structure before it disintegrates, and that the diffraction pattern can be evaluated uniquely to reconstruct the object’s structure. The authors expect that later on, when pulses with shorter wavelengths become available, macromolecules can be imaged in a similar way.

A beam of ultrafast (25 fs) pulses, each containing about 1012 photons, was focused onto the silicon nitride membrane containing the object pattern (two stick figures and a star), supplying a power density of 4 × 1013 W/cm2 (see figure). The membrane spanned a 20-mm-wide rectangular window in the sample plate.

The light scattered from the window containing the pattern was collected by a mirror and reflected to a CCD array at an on-axis distance of 55 mm, while the unscattered beam passed through the mirror via a central hole. The multilayer mirror was designed to yield optimum reflectivity for the locally varying angles of incidence. In this way, a single x-ray shot generated a diffraction pattern that contained a rectangular cross due to diffraction at the edges of the rectangular window in the sample holder, and in addition a speckle pattern generated by the object pattern that extended to a 15° angle. A central “black hole” was due to the hole in the mirror, which passed a direct beam.

Two characteristic speckle sizes can be seen in the diffraction pattern, one relatively large and the other very small. The larger speckles arise from interference within the narrow (submicrometer) inner apertures of the stick figures, corresponding to single-slit diffraction; the smaller speckles are a result of diffraction encompassing both stick figures and the star. A second, subsequent x-ray shot produced predominantly a rectangular cross as the diffraction pattern, demonstrating that the preceding pulse had destroyed the object (this was confirmed by a scanning-electron micrograph).

The mathematical reconstruction closely matches the original object pattern. The DESY experiment has shown that a fundamental principle of physics—that of the inertia of mass—can be exploited for destructive x-ray imaging of microscopic masses, if at a sufficiently small time scale.

REFERENCES

1. R. Neutze et al., Nature 406, 752 (2000).

2. H. N. Chapman et al., Nature Physics 12 (November 2006).

3. V. Ayvazyan et al., Eur. Phys. J. D 37, 297 (2006).

Uwe Brinkmann | Contributing Editor, Germany

Uwe Brinkmann was Contributing Editor, Germany, for Laser Focus World.