New TFT technology could replace LTPS for OLED, LCD, and solar devices

Solar-Tectic (ST; Briarcliff Manor, NY), with assistance from Binghamton University (Binghamton, NY) and Blue Wave Semiconductor (BWS; Baltimore, MD), has patented new thin-film-transistor (TFT) technology that will increase efficiency and luminance while decreasing cost for organic light-emitting diodes (OLEDs), active-matrix OLEDs (AMOLEDs), and liquid-crystal device (LCD) displays, as well as solar cell devices.

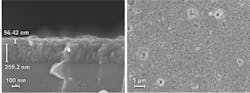

Unlike conventional low-temperature polysilicon (LTPS) processes used to manufacture the TFTs that drive the pixels in a display and require expensive excimer-laser annealing, the new process is a variation of metal-induced crystallization (MIC) and uses a modified liquid-phase-epitaxy (or vapor-liquid-solid) electron-beam process at low temperature (as low as 232°C) to deposit a thin layer of metal onto a metal oxide such as a magnesium oxide (MgO) buffered substrate, after which the final vaporized silicon (Si) layer is deposited and crystallizes into an approximately 50- to 100-nm-thick film without metal residue. Using Raman and x-ray spectroscopy, analysis of the Si film revealed a very high electron mobility of 188 cm2/Vs (compared to the typical 100 cm2/Vs for LTPS). The researchers expect to improve electron mobility even further by using ST’s and BWS’s oriented MgO (111) film buffered substrates to further increase crystal size. Reference: P. P. Rajbhandari et al., Mater. Lett., 219, 138–142 (2018).

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.