RON OLSON

As retailers struggle to come up with new in-store visual effects, holographic imagery and display devices are about to deliver on a 30-year-old promise. Display holography came into being and was immediately touted as the next big thing in visual display about the time Richard Nixon was getting comfortable in the White House. And one might say that the commercial career of holographic portraiture taken with ruby lasers met its own Watergate because of a characteristic that it held in common with political cartoons: unflattering images.

So it's not surprising that I get looks of disbelief now when I tell people that laser portraiture has improved to the point that Laser Reflections (San Francisco, CA) includes 20 Playboy Playmates among its "tickled-pink" customers. The skepticism fades, however, when I remind people that laser technology has been anything but stagnant during the last three decades. Today, a number of leading-edge studios are betting that high-resolution, three-dimensional (3-D) images—as enabled by new lasers—will find immediate entry into high-end displays ranging from museums and trade shows to storefront windows and tavern walls.

My company uses a purely analog approach to holography: we record 3-D information in a single 10-ns pulse of green light—the output of a hybrid Nd:YAG/Nd:glass laser built specifically for portraiture. The shortcomings of the prior source (ruby laser) stemmed from trying to image water-based tissues with red-bordering-on-infrared light. The 532-nm exposures taken in our studio gallery are just green enough to ensure a clean first-surface reflection from skin and fast enough to eliminate motion as a concern in the imaging process. With the ability to produce better portraits, we see a substantial market in retail displays.

Why holography?

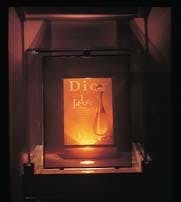

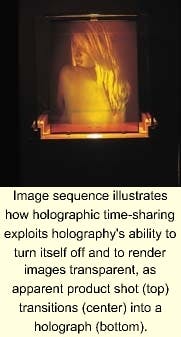

With this in mind, we have designed a uniquely holographic time-sharing technique with an oscillating light source to alternate the viewer's attention between a 3-D image (in front) and a real product (sized from wristwatches to basketballs) in back (see photos). A somewhat less-esoteric technique, holophotography, is poised to enable a new generation of signs to compete with neon. The limited viewing angle is more than compensated for by the increased pizzazz.

Constraints on size resulting from limitations imposed by the commercial plate suppliers will be addressed at some point with our own coating machinery or by shifting our work from coated glass plates to film (currently available on rolls up to 1 m wide). Yet, in an advertising industry consumed by the issue of size, holography can invite viewers within arms reach rather than intimidating them into the distance. Holophotography supports more than 1000 times the resolution of photography, and the depth (z-axis) in holophotography remains constant, facilitating smaller and more magical (x and y) images. In addition, coherent light supports 5000-line/mm resolution on a photosensitive emulsion; for a recent project we made a paneled window array of nine 40 x 30-cm images.

Expanding prospects

Four-year-old Zebra Imaging (Austin, TX) routinely addresses issues of size with two products. One, called Mosaic, is a full-color, full-parallax hologram generated from digital data and printed to any size (the largest to date being 6 x 18 ft) in 2 x 2-ft increments. The other, Reflections, consists of 2 x 2-ft replicated full-color, full-parallax holograms sold with an optional integrated light source.

Zebra cofounder Michael Klug sees three primary areas in which their holograms have broad and potentially high-volume use. The first is in manufacturing, where enhanced 3-D visual communication might significantly streamline the product design-and-development process. The second is in advertising signage, as in point-of-purchase and trade-show applications, in interior decorating such as lobbies, in conference rooms, and in entertainment venues such as movie theaters, theme parks, and sports arenas. The third is in promoting events, tourist sites, or celebrities.

Most of the images we produce at Laser Reflections use a standard low-voltage halogen bulb as the illumination source. With a 35–50-W bulb and a dichroic filter, we can resolve 30 cm of in-focus scene depth and support ~15 cm of image projection. If we substitute a laser as the playback source, however, these numbers change to more than 2 m of resolvable scene depth and more than 1 m of forward projection—enough to travel through a storefront window and onto the sidewalk for a passersby to ponder.

With diode-pumped solid-state (DPSS) lasers now available that supply up to 50 mW at 532 nm for less than $1500 (and decreasing), we believe the market for laser-lit imagery will grow substantially, particularly when we can find a coherent source of light in the amber-orange region (~570 to 590 nm). With that in mind, we've designed a laser projector consisting of a DPSS laser (or a laser diode), a fast optic, and a high-speed rotating mirror. Such a device was recently delivered to the Pacific Science Center (Seattle, WA) and expands the beam to uniformly backlight transmission holographs up to 60 x 50 cm.

In addition to our commercial projects, we are establishing the Bay Area Center for Holography with the goal of producing a corporate-sponsored library of traveling exhibits to include collections of the world's indigenous peoples and endangered animal species. The unretouchable nature of holography—once thought to be an Achilles' heel—now stands, in terms of archiving, as one of the technique's real strengths.

Ron Olson is a cofounder of Laser Reflections Inc., 589 Howard St., San Francisco, CA 94105; e-mail: [email protected].