TOKYOMatsushita Research Institute Tokyo has created a trial version of a parallel image-processing device that uses free-space optical interconnections. To process images that respond to external fields in real time, pixel-level processing must be made parallel. A two-dimensional array of many processing elements can be created; however, managing the input and output of image information becomes difficult. It is necessary to develop a method that can be used with many elements but for which transmission time does not slow processing speed. The Matsushita device uses free-space optical interconnections to achieve these goals.

Digital processing element

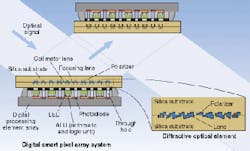

Researchers at the University of Tokyo have provided the Matsushita group with a digital processing element (DPE) array, to which the group has added additional elements such as light-emitting diodes (LEDs) and optical components using its own mounting technology. This makes it possible for the DPE to send and receive image information in parallel using light (see figure).

Digital processing element array contains precisely aligned photodiodes and light-emitting diodes. Diffractive microlenses and deflectors direct light from pixels in one array to pixels in the next.

The DPE array is an 8 x 8-pixel parallel-processing device. Each image component has a numerical/logical processing unit, resistor, photodiode, and LED controlling circuit. Commands are given externally, and single-instruction multiple-data processing is used.

Input from the photodiode is stored in the resistor, and the commands are executed in order at a clock frequency of 10 MHz. The calculations within one image component are executed while the component communicates with the neighboring four image components; results are supplied to the LED controlling circuit. The program can be fed in externally, giving the image-processing system a high degree of flexibility.

The device requires optical input and output elements. For precise positioning of the elements, the Matsushita group has placed a silicon layer with holes on top of the DPE array; when LEDs and photodiodes are inserted into the holes, they are automatically aligned.

An array of diffractive optical components channel the optical signal from outside to the photodiodes, as well as aim the LED light in the right direction. Diffractive micro-optical elements analogous to lenses and deflectors, respectively, have been created on two silica surfaces, with the diffractive elements facing each other. By creating such a structure, the smart pixels can be connected in multiple layers, making high-speed processing possible.

The photodiodes have already detected signals within a 25-ms period in a setup having the pixel arrays linked by the diffractive optical system. The DPE is fast enough to process 1000 frames per second. Increasing the intensity of the input beam on the photodiodes enables faster processing because the detection time becomes shorter. Increasing light-collection efficiency is the next crucial step. The research group plans to develop a 16 x 16-pixel device and demo system within the next two years.

Courtesy O plus E magazine, Tokyo