Molybdenum image sensor is 5X more sensitive than silicon

Recognizing that monolayer molybdenum disulfide (MoS2) is a direct-bandgap semiconductor due to quantum-mechanical confinement and allows a high absorption coefficient and efficient electron-hole pair generation under photoexcitation, researchers at École Polytechnique Federale de Lausanne (EPFL; Lausanne, Switzerland) have been able to fabricate MoS2-based photodetector devices that are five times more light-sensitive than silicon; photoresponsivity values reach 880 A/W—a 100,000-fold improvement over previous reports for monolayer MoS2 phototransistors.

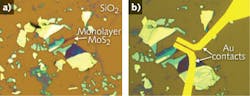

The photodetectors were fabricated using scotch-tape micromechanical cleavage (similar to some graphene-fabrication techniques) to exfoliate the MoS2 monolayer from molybdenum-doped materials. Monolayer MoS2 flakes were identified based on their optical contrast with respect to the underlying silicon dioxide substrate; 90-nm-thick gold electrodes were then placed on the monolayers and devices were wire-bonded. Because of the direct bandgap, the ultrasensitive MoS2 photodetectors have a photoresponsivity that is 106 better than the first graphene photodetectors, with a 9000-fold higher photoresponsivity observed in monolayer MoS2 compared to multilayer photodetectors. In contrast to silicon photodiodes, MoS2 photodetectors devices consist of a simple n-type channel—much easier to manufacture than a p-n junction and potentially leading to lower production costs. Contact Andras Kis at [email protected].

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.