Kirana ultrahigh-speed camera studies composite material failure

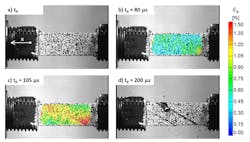

The Institute for Carbon Composites (LCC) at the Technical University of Munich, Germany is using a Kirana ultrahigh-speed camera from Specialised Imaging (Tring, England) to record high-resolution images of a unidirectional carbon-epoxy composite material undergoing dynamic tension testing on a split-Hopkinson Tension Bar. The experimental setup was to determine the mechanical properties of carbon epoxy composites under high strain rates (100 – 1000 1/s). The deformation and the failure patterns of these composite materials, was observed and recorded in tests that lasted less than 200 microseconds.

RELATED ARTICLE: How to choose a high-speed camera: Understanding new imaging sensors and techniques

Using the Kirana camera has provided the LCC with the ability to capture high-resolution images of the ultrahigh-speed events that often occur when undertaking dynamic tension tests. Taking up to 5,000,000 frames per second, and shuttering every 100 nanoseconds, there is no compromise in capturing high-quality data. The data is exported in 180 frames so each test can be easily saved and viewed.

Using the images captured by the Kirana ultrahigh-speed camera, the LCC researchers imported them into state-of-the-art Digital-Image-Correlation (DIC) software enabling the calculation of the in-plane strain-field. In addition, the images revealed useful information regarding the deformation and failure mechanisms of the specimens.

Founded in May 2009, the Institute for Carbon Composites (LCC) undertakes fundamental research and application-oriented industry cooperation in the field of fiber-reinforced composites. Experimental methods are of great importance for the investigation of material behavior and the further development of fiber-reinforced polymer matrix composites. At the LCC a broad spectrum of state-of-the-art test methods and equipment is available for the determination of the physical and mechanical properties of matrix systems and laminates. In addition to the application of various standards, the LCC also investigates and develops new and innovative testing techniques (see http://www.lcc.mw.tum.de/en/home/).

SOURCE: Specialised Imaging; http://www.specialised-imaging.com

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.