Flexible (including disposable) display market to approach 800 million units by 2020

El Segundo, CA--Demand for flexible displays is predicted to undergo massive growth during the next seven years, with a broad variety of applications (ranging from smartphones to giant building-mounted screens) driving a nearly 250X expansion in shipments from 2013 through 2020, according to a new report called "Flexible Display Technology and Market Forecast," created by IHS, an analytics company.

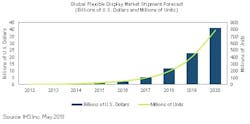

Global shipments of flexible displays are projected to soar to 792 million units in 2020, up from 3.2 million in 2013. Market revenue will rise to $41.3 billion, up from just $100,000 during the same period (see figure).

Related: World's largest flexible OLED display developed by ASU Flexible Display Center

Related: E Ink flexible display to be used on two-screen Russian smart phone

Related: More flexible display news: full-color AMOLED video from ASU and Universal Display

Rigid, to flexible, to disposable

IHS classifies flexible displays into four generations of technology. The first generation is the durable display panels that are now entering the market. These panels use a flexible substrate for thinness and ruggedness. However, these displays are flat and cannot be bent or rolled.

Second-generation flexible displays are bendable and can be molded to curved surfaces, for example on small-form-factor products like smartphones.

The third generation consists of truly flexible and rollable displays that can be manipulated by end users. These displays will enable a new generation of devices that save space—for example, a tablet-sized display that rolls up to be as small as a smartphone.

The fourth generation consists of disposable displays that cost so little that they can serve as a replacement for paper.

Starting small

Flexible displays are expected to initially be used in smaller-sized products, such as mobile phones and MP3 players. However, once large-size displays are available, flexible technology will be used in bigger screen-size platforms, such as laptops, monitors, and televisions.

The largest application for flexible displays during the next several years will be personal electronic devices. This segment will be led by smartphones, with shipments climbing to 351 million units by 2020, up from less than 2 million this year.

Flexible at SID

Flexible displays were a major topic at the Society for Information Display (SID) Display Week event in Vancouver, BC, Canada in May, 2013.

During a SID keynote address, Kinam Kim, president and CEO of Samsung Display Co., discussed his company’s flexible organic light-emitting diode (OLED) display technology. Kim said that the technology will be suitable for wearable electronics devices like Google Glass.

Also at SID, LG Display showed a 5-inch OLED panel constructed from plastic that was both flexible and unbreakable. Corning at SID showed its Willow Glass, which can be used as with both OLEDs and liquid-crystal displays (LCD) in mobile devices such as smart phones, tablets and notebook PCs. Because of its thinness, strength and flexibility, Willow Glass could enable future displays to be wrapped around a device or a structure.

IHS predicts that OLEDs will be the leading flexible display technology during every year for the foreseeable future, accounting for 64% of shipments in 2020.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.