Hollow-core dielectric-coated fibers deliver mid-IR laser light

Torrance, CA--Scientists from Opto-Knowledge Systems, Inc. (OKSI; Torrance, CA), Pacific Northwest National Laboratory (Richland, WA), and Rutgers University (Piscataway, NJ) have developed a new type of hollow-core optical fiber that can deliver mid-infrared (mid-IR) as well as long-wavelength infrared (LWIR) laser light. The fibers, detailed in "Fiber delivery of mid-IR lasers" from the SPIE Newsroom (August 24, 2011), are important for mid-IR light delivery from quantum-cascade lasers (QCLs) and other mid-IR sources in instruments that candetect trace molecular species in such applications as explosives detection, environmental pollutant monitoring, and in analysis of biomarkers in a patient’s breath.

Although mid-IR light delivery is possible using solid-core chalcogenide glasses, these chalcogenide fibers are extremely brittle if impurities are not controlled. In addition, transmission is attenuated strongly at long wavelengths, with a working limit of about 6 microns for sulfide and 9 microns for selenide glass types of chalcogenide fibers.

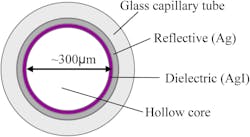

The hollow-core fibers were manufactured by pumping a silver solution through glass tubing, creating a smooth silver layer on the inside of the tube. An iodine solution is then pumped through the tube, which forms a dielectric silver iodide (AgI) layer upon reaction with the silver. The glass tubing provides a smooth, robust, and flexible structure on which to deposit the coatings. For most mid-IR applications, AgI is used as the dielectric material, and its thickness can be optimized for specific wavelengths. In general, the process produces two broad classes of fibers: single-mode fibers for long-wave infrared (LWIR) applications operating from 6 to 14 microns, and multimode, low-loss fibers for broadband applications operating between 3 and 14 microns.

In addition to preserving a Gaussian profile on bending, the single-mode fibers exhibited mode filtering; a beam from a QCL with an elliptical shape and fringes was cleaned-up by the hollow fiber, resulting in a circularly symmetric (Gaussian) output.

SOURCE: SPIE Newsroom; http://spie.org/x52092.xml?ArticleID=x52092

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.