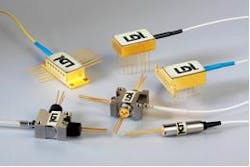

OSI Laser Diode Inc. (LDI; Edison, NJ), an OSI Systems Company and optoelectronics manufacturer of high power lasers, APD detectors, receivers, and transmitter and receiver modules, has established a supply agreement with SemiNex Corp. (Peabody, MA), a manufacturer of high power laser diodes. Under the supply agreement, SemiNex will fulfill LDI’s needs for high power indium phosphide laser chips in the infrared wavelength range of 1300 nm to 1700 nm.

"The SemiNex and LDI teams have worked together for several years to develop and supply industry-leading laser components to the telecommunications, military and industrial markets. We are pleased that LDI has formalized the relationship with SemiNex as their partner for indium phosphide laser diodes," said David Bean, SemiNex CEO.

Rollin Ball, president of OSI Laser Diode, stated, “Many factors went into the decision to choose SemiNex, including product dependability, supply stability, and cost effectiveness. SemiNex offered LDI unmatched performance and reliability. Choosing SemiNex to supply our high power IR laser needs further establishes LDI as the worldwide leader in laser diode supply.”