Yet another use for graphene: CGC and Plastic Logic create graphene-based flexible display

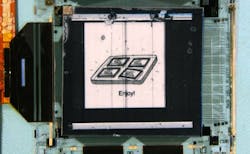

A flexible display incorporating graphene in its pixels' electronics has been successfully demonstrated by the Cambridge Graphene Centre (CGC) at the University of Cambridge and Plastic Logic (both in Cambridge, England), the first time graphene has been used in a transistor-based flexible device, says the CGC.

The new prototype is an active-matrix electrophoretic display, similar to the screens used in today's e-readers, except it is made of flexible plastic instead of glass. In contrast to conventional displays, the pixel electronics, or backplane, includes a solution-processed graphene electrode, which replaces the sputtered-metal electrode layer within Plastic Logic's conventional devices, increasing flexibility.

The new 150-pixel-per-inch (150 ppi) backplane was made at low temperatures (less than 100°C) using Plastic Logic's organic thin film transistor (OTFT) technology. The graphene electrode was deposited from solution and subsequently patterned with micron-scale features to complete the backplane.

For this prototype, the backplane was combined with an electrophoretic display; future demonstrations may incorporate liquid-crystal (LC) or organic LED (OLED) technology to achieve full color and video functionality.

Medical-imaging uses also

These lightweight flexible active-matrix backplanes can also be used for sensors, with novel digital medical-imaging and gesture-recognition applications already in development.

This joint effort between Plastic Logic and the CGC was recently boosted by a grant from the UK Technology Strategy Board, within the "realising the graphene revolution" initiative. This will target the realization of an advanced full-color OLED based display within the next 12 months.

The project is funded by the Engineering and Physical Sciences Research Council (EPSRC) and the EU's Graphene Flagship.

Source: http://www.cam.ac.uk/research/news/first-graphene-based-flexible-display-produced

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.